A word about abandoned mines!

Many of the environments presented on this website are perilous and were only accessed with a thorough understanding of the hazards present and the necessary precautions to mitigate them. This often involves engaging the expertise of professional miners or underground search and rescue teams who possess a comprehensive understanding of the abandoned workings, airflow patterns, and specific hazards inherent to a particular location. Never enter an abandoned mine without the appropriate training, people, equipment, and protocols in place.

It is important to note that mines were not constructed with longevity in mind and many that were built over a century ago now present a plethora of hazards such as unstable rock formations, deteriorated timber supports and ladders, unexpected drops, and the potential for sudden roof collapses. Additionally, the presence of invisible and flammable gasses or lack of oxygen, heighten the risk of injury or death. In coal mines, the presence of methane and black damp must be taken into careful consideration. Furthermore, barometric changes above ground can cause shifts in airflow underground which can trap individuals in areas with poor air quality, making escape impossible.

STAY OUT AND STAY ALIVE!

Steam Hoisting Engine and Ore Cart - Abandoned Coal Mine - Pennsylvania

Carbide lamp - Photographed from the collection of The Lackawanna Historical Society. These early miner’s lamps had an exposed flame which could ignite flammable gases that collected in mines, causing explosions.

Permissible Safety Lamp - Permissible lamps were designed to operate in air that may contain coal dust or gases, both of which are potentially flammable or explosive. Open flame lamps could ignite flammable gases which collected in mines, causing explosions; safety lamps were developed to enclose the flame and prevent it from igniting the surrounding atmosphere.

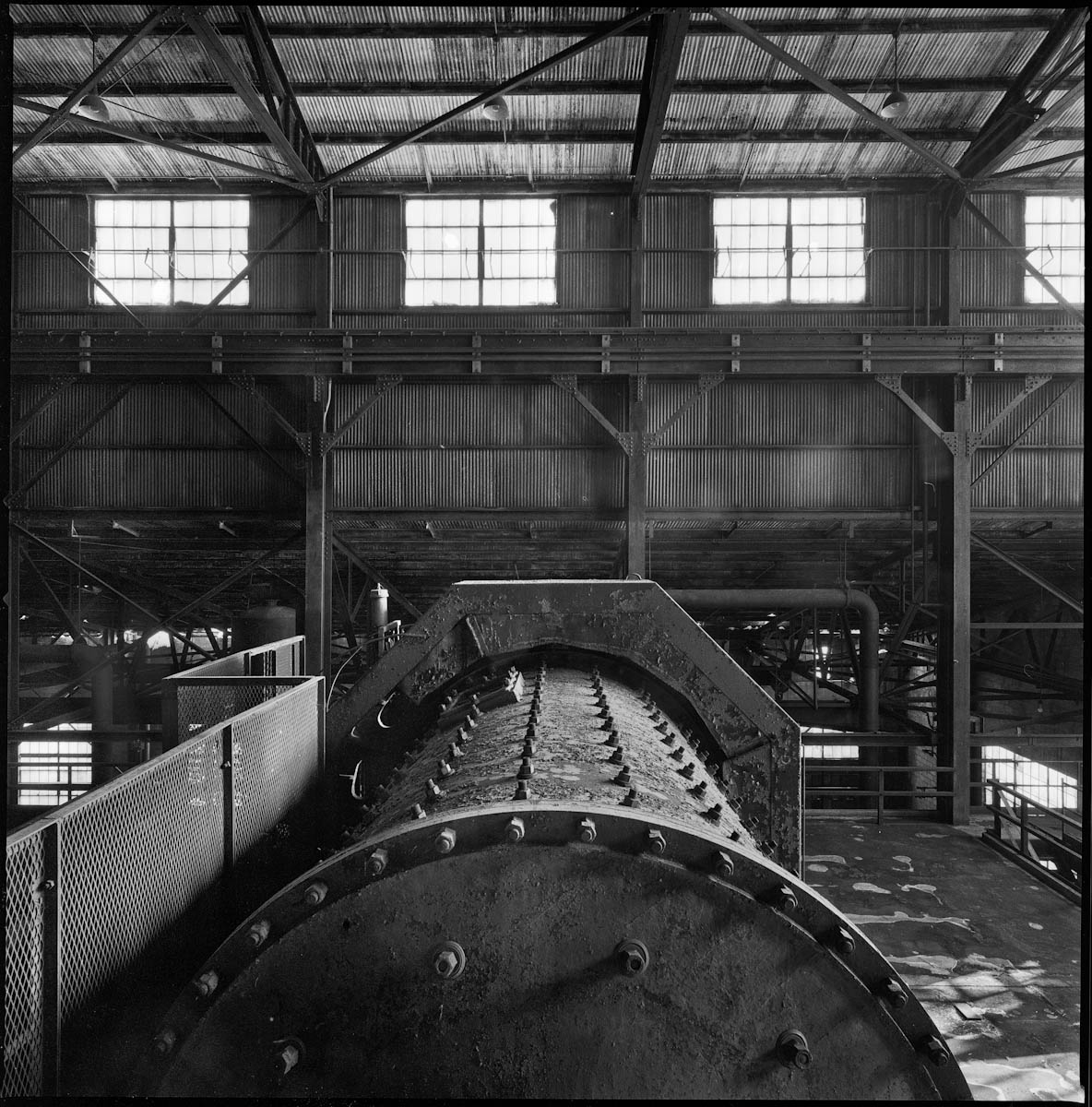

A coal conveyer moves material from a mine to a processing facility - Pennsylvania

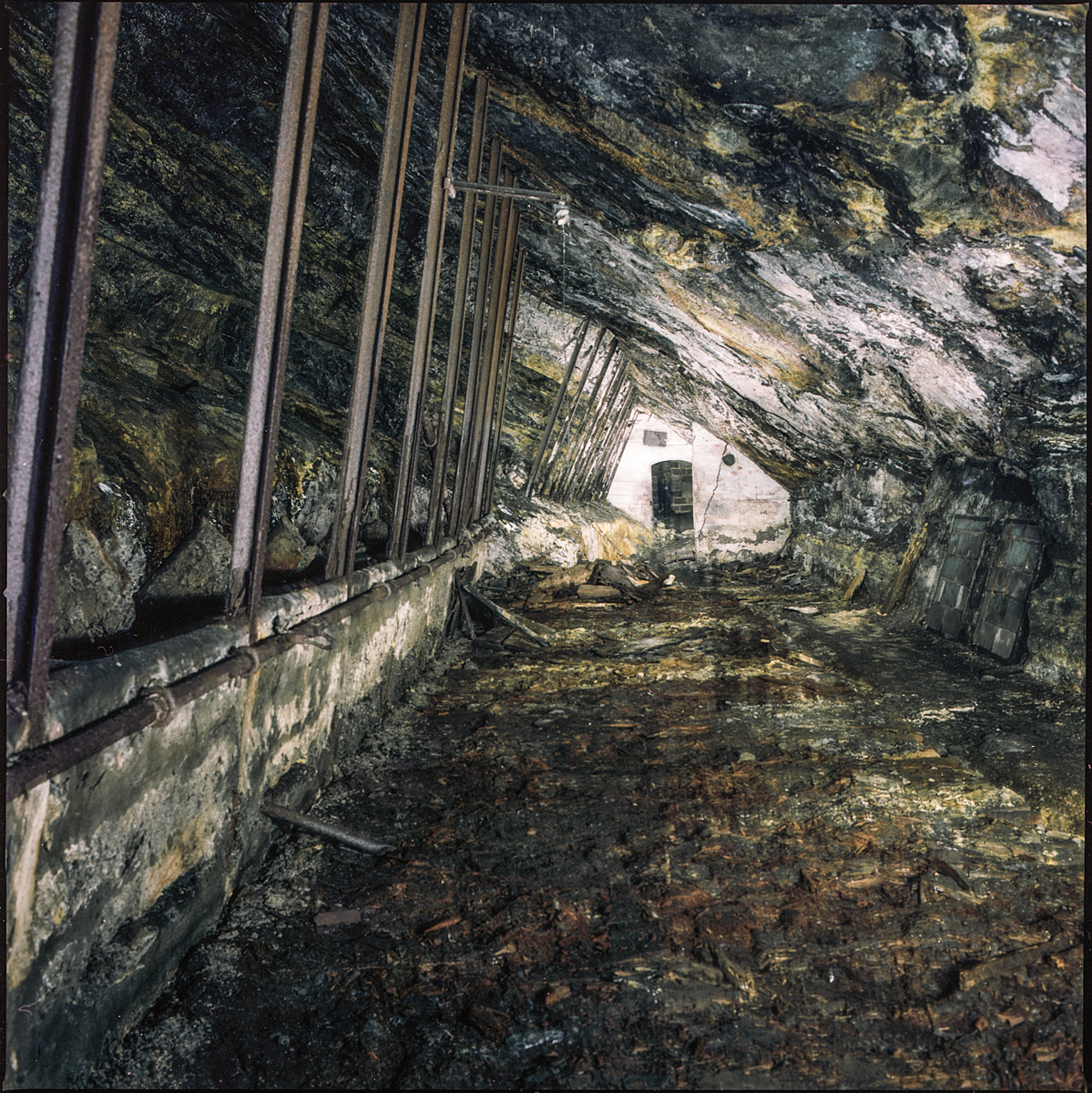

A coal conveyer moves material from a mine to a processing facility - Pennsylvania Rail cars and electrical wires in a gangway abandoned deep below Pennsylvania.

Rail cars and electrical wires in a gangway abandoned deep below Pennsylvania.  Drainage Adit - Centralia PA

Drainage Adit - Centralia PA

The Assumption of the Blessed Virgin Mary - Ukrainian Catholic Church - Centralia PA

The Assumption of the Blessed Virgin Mary - Ukrainian Catholic Church - Centralia PA One of very few surving structures in the once thriving coal mining town that has suffered from an undground coal mine fire since since 1962 and continues to burn to this day.

Acid mine drainage - Centraila PA

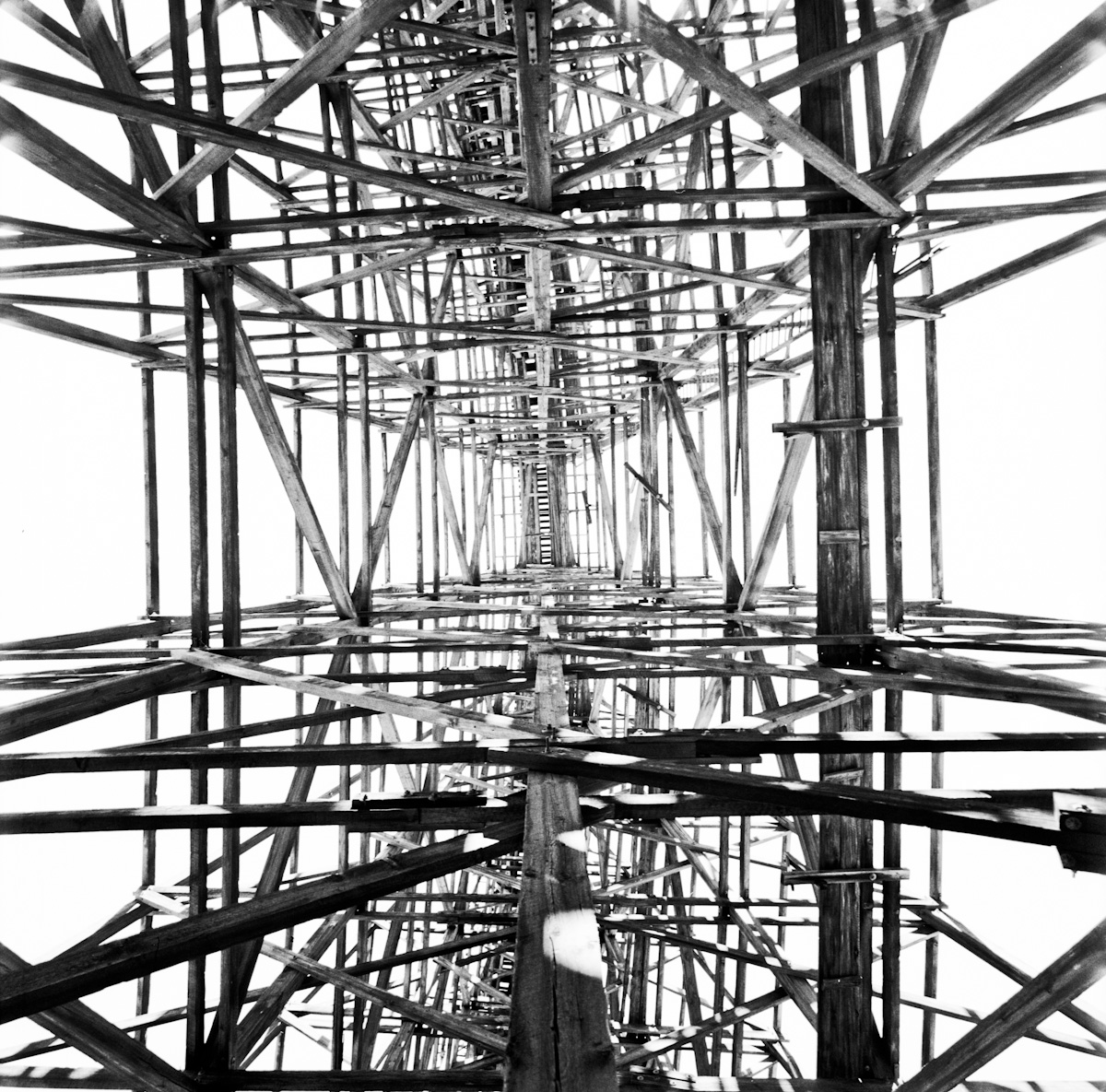

Huber Coal Breaker - Ashley PA -

demolished

Huber Coal Breaker - Ashley PA -

demolished

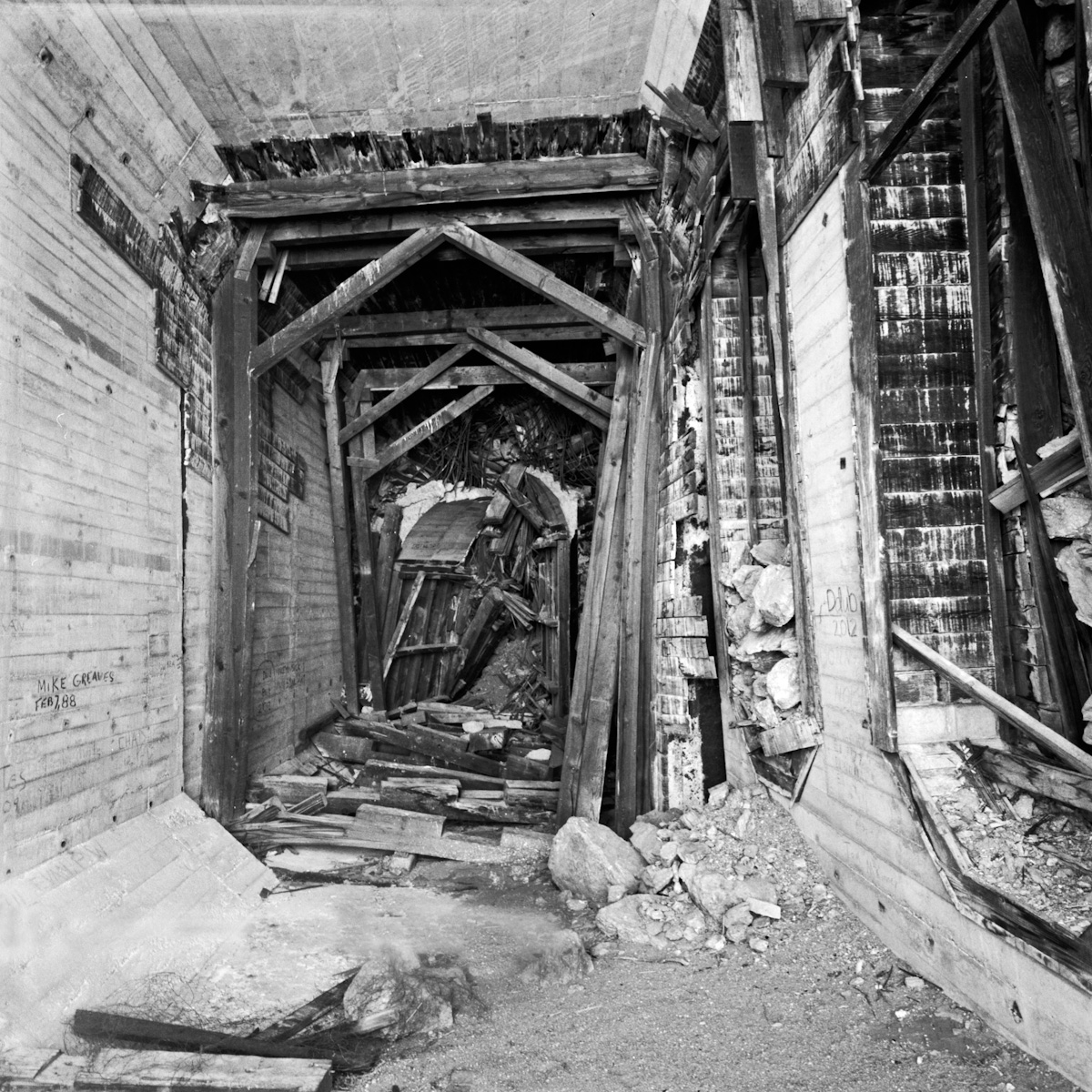

Abandoned Coal Mine - Pennsyvlania

Underground Coal Mine Fire - Pennsylvania

Underground Coal Mine Fire - Pennsylvania

Abandoned Coal Mine - Pennsyvlania

Abandoned Coal Mine - Pennsyvlania

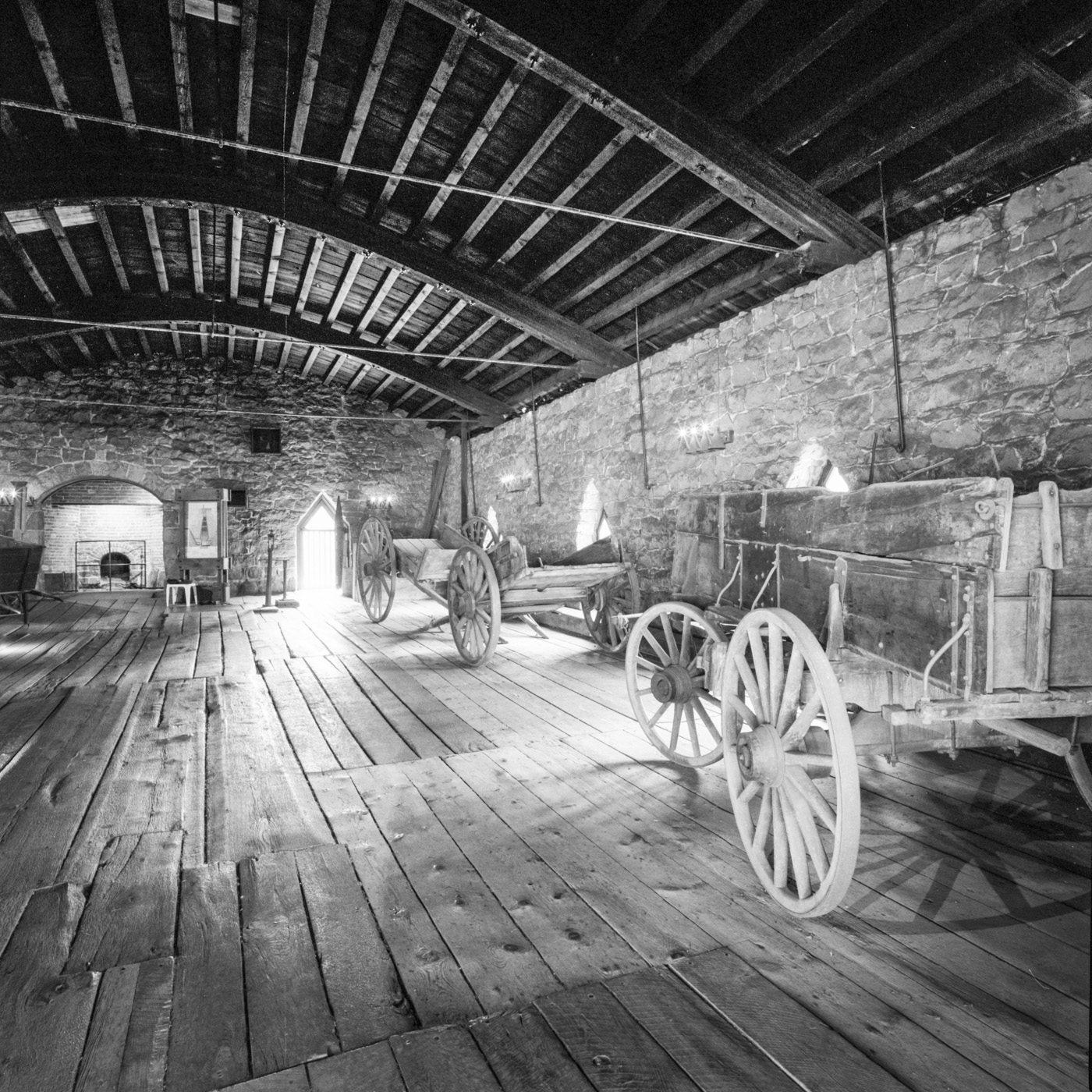

Mule Barn - Abanonded Coal Mine - Pennsylvania

Huber Coal Breaker - Ashley PA -

demolished

Airflow Gauge - Photographed from the collection of the Scranton Historical Society

Airflow Gauge - Photographed from the collection of the Scranton Historical Society

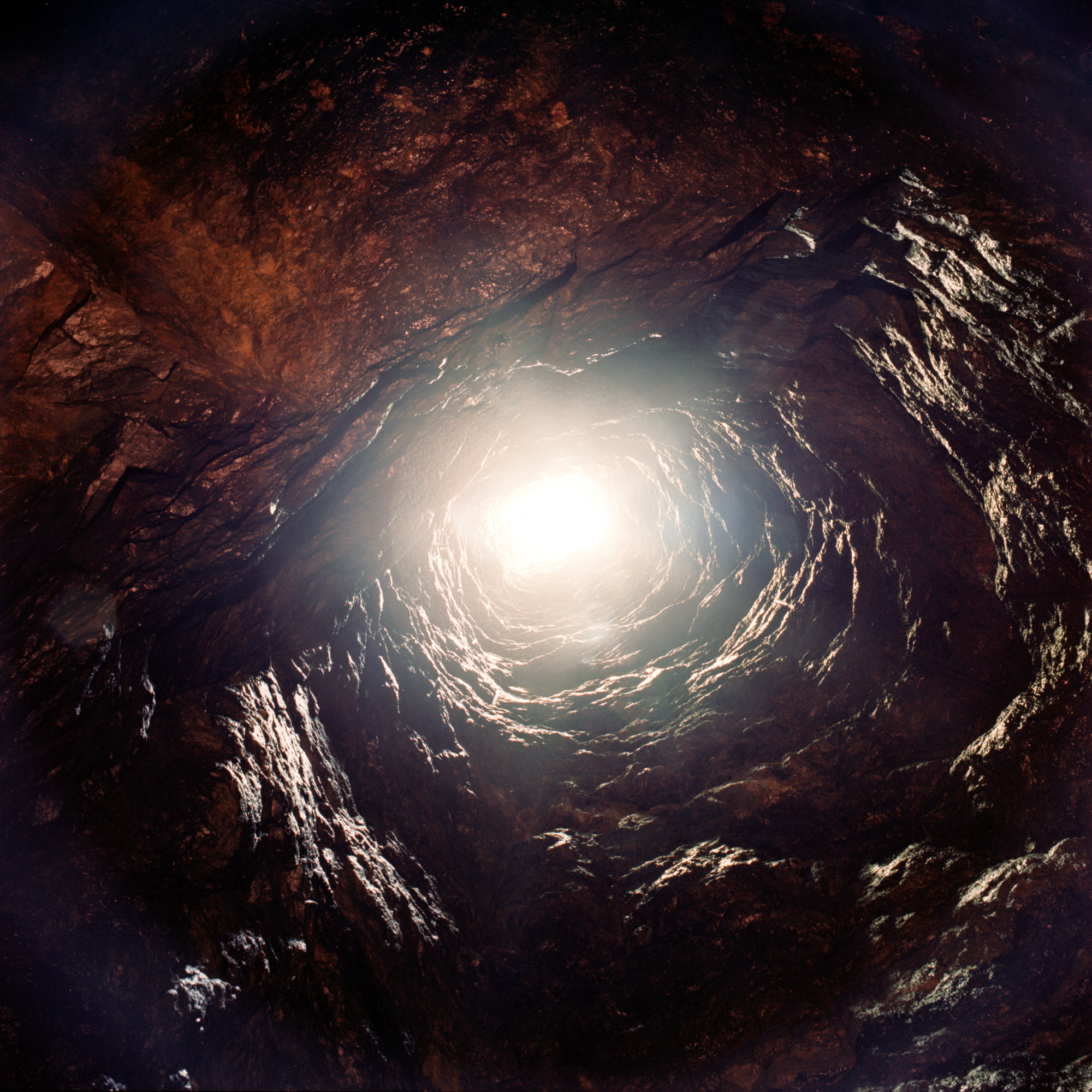

Coal mine shaft - Pennsylvania

Coal mine shaft No.2 - Pennsylvania

IRON

Splitrock (Cobb) Furnace #1 - New Jersey - 1862

Splitrock (Cobb) Furnace #1 - New Jersey - 1862

Splitrock (Cobb) Furnace #2 - New Jersey

Clove Furnace - New Jersey - Completed 1865

Clove Furnace - New Jersey - Completed 1865

Cornwall Furnace - Pennsylvania - 1742

Photographed 2018

Cornwall Furnace - Pennsylvania - 1742

Photographed 2018

Cornwall Furnace - Charging Floor - Pennsylvania - Built 1742 Photographed 2018

Sterling Furnace - New York

Believed to have been the first place in the State of New York in which iron and steel were manufactured in quantity.

Sterling Furnace - Hoist House Ruins - New York

PLAQUE ONSITE READS:

From the iron here produced was manufactured in 1778, by Peter Townsend, the Great Chain put across the Hudson River, near West Point, to impede the progress of the British war-ships up the river; and the first anchor made in New York State was here manufactured in 1773.

Erected 1906 by Daughters of the Revolution.

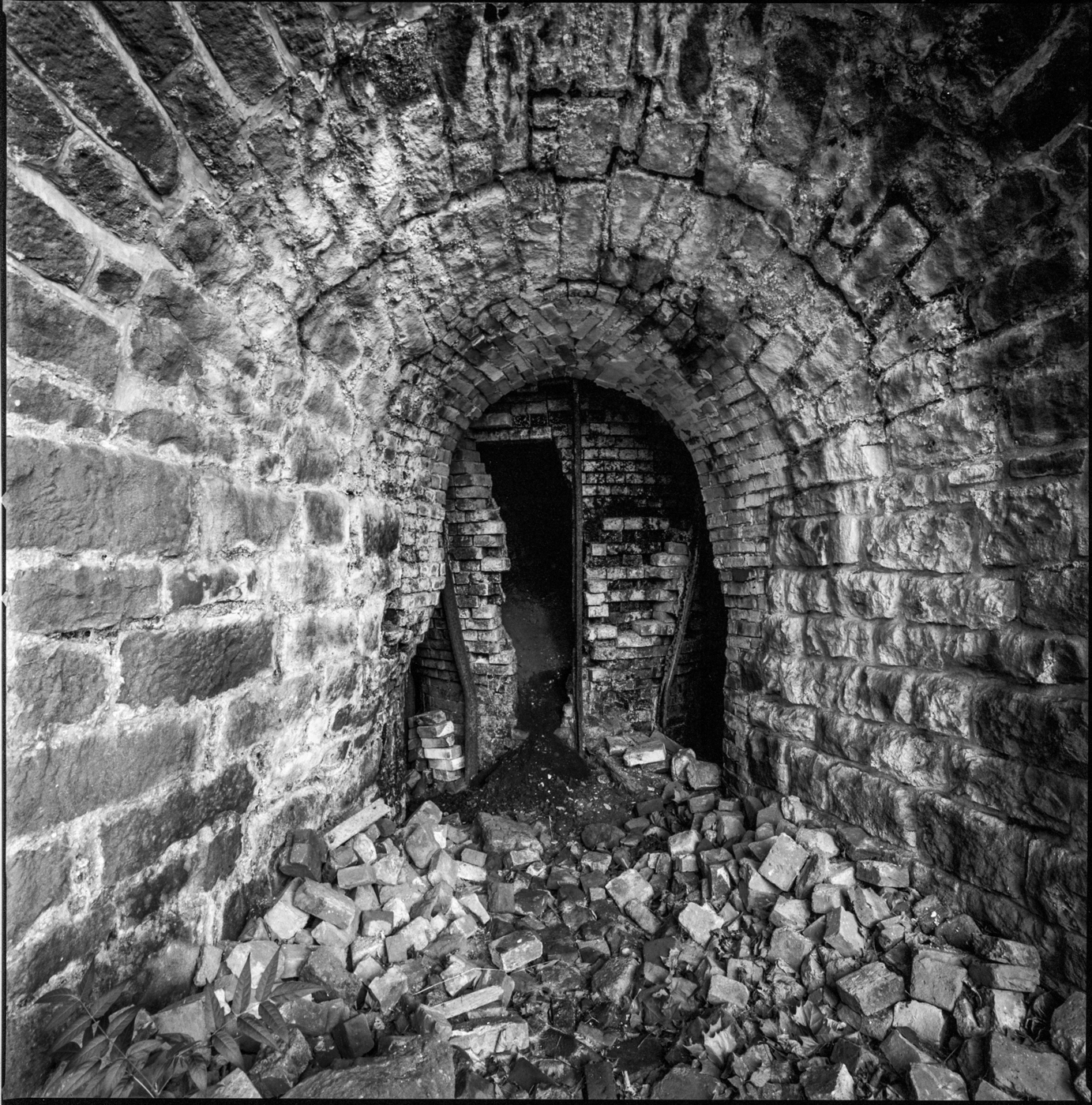

West Point Foundry furnace remains - New Jersey - 1817

West Point Foundry furnace remains - New Jersey - 1817

Joanna Furnace - Pennsylvania

Joanna Furnace - Pennsylvania

Joanna Furnace - Pennsylvania

Joanna Furnace - Pennsylvania

Clove Furnace - New Jersey

Hopewell Furnace - Pennsylvania - 1771

Hopewell Furnace - Pennsylvania - 1771

Hopewell Furnace - Pennsylvania - 1771

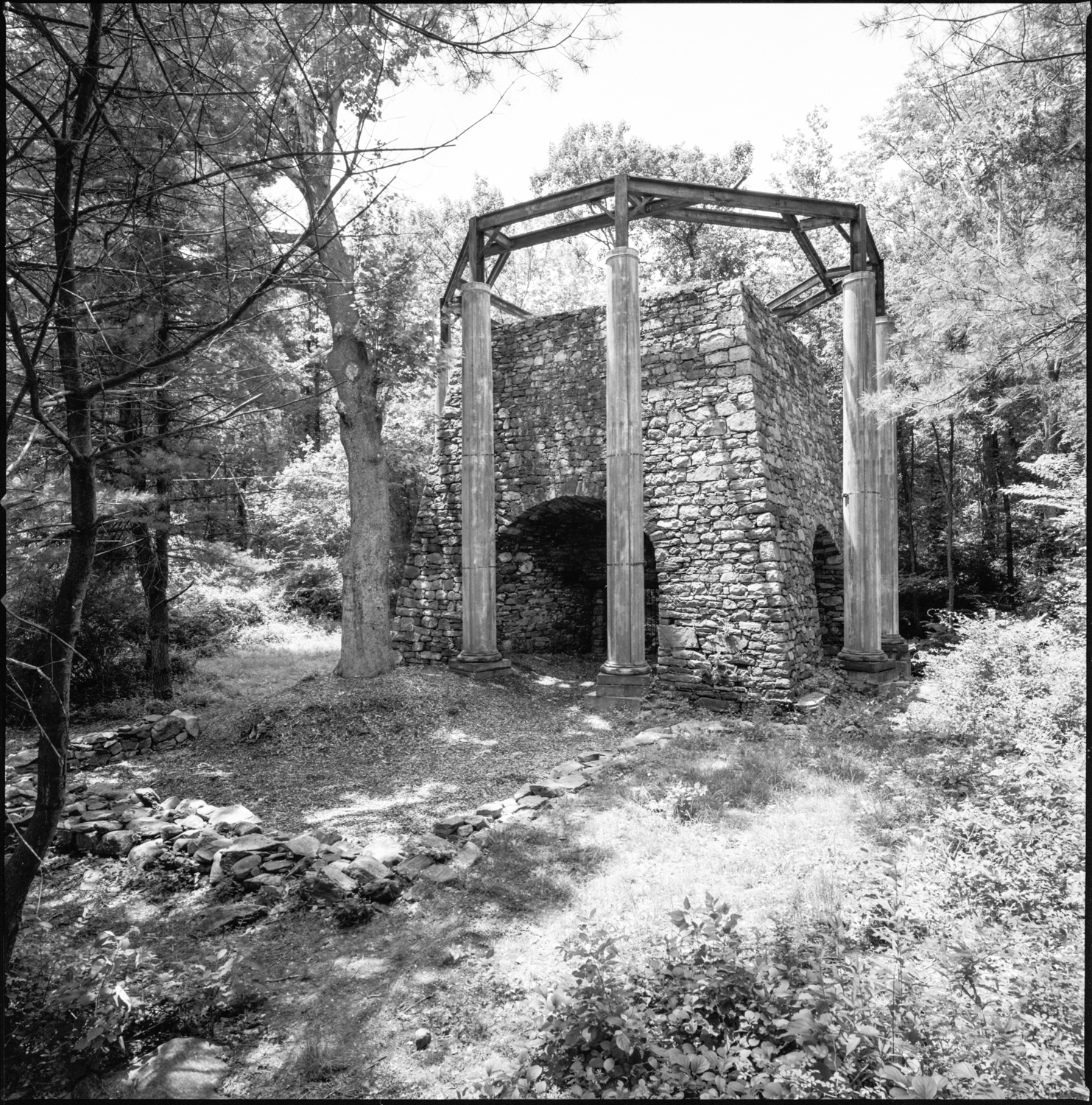

Splitrock Furnace #3 - New Jersey - 1862

Splitrock Furnace #3 - New Jersey - 1862The Splitrock Iron Furnace

Located in Morris County, New Jersey, it was built in 1862 during the height of the American Civil War. The furnace was constructed by the Split Rock Iron Company, which was formed by a group of local investors who saw the potential for iron production in the area. The furnace was built near a large deposit of iron ore and was powered by a nearby stream, which provided the necessary water to power the furnace's blast machinery.

Splitrock Furnace #4 - New Jersey - 1862

During its peak production years, the furnace produced over 400 tons of iron per month and employed over 200 workers. The iron produced by the furnace was used for a variety of purposes, including the production of weapons and ammunition for the Union army during the Civil War. The furnace also produced iron for other industrial uses such as railroads, bridges, and buildings. However, after the end of the war, demand for iron dropped significantly, and the Splitrock Iron Furnace was forced to close in 1866.

During its peak production years, the furnace produced over 400 tons of iron per month and employed over 200 workers. The iron produced by the furnace was used for a variety of purposes, including the production of weapons and ammunition for the Union army during the Civil War. The furnace also produced iron for other industrial uses such as railroads, bridges, and buildings. However, after the end of the war, demand for iron dropped significantly, and the Splitrock Iron Furnace was forced to close in 1866.

The Oxford Iron Furnace - Built 1741 - Oxford, NJ

The Oxford Iron Furnace - Built 1741 - Oxford, NJThe Oxford Iron Furnace

Represents the early development of the iron industry in the United States during the 18th and 19th centuries. The furnace was built in 1741 and was in operation until 1884, producing iron for various purposes such as weapons, tools, and machinery. The furnace is notable for its use of charcoal as a fuel source, which was the primary fuel used in iron production during the colonial period. The furnace also utilized a blast mechanism, which was a significant technological advancement at the time, that increased the efficiency of the iron production process.The Oxford Iron Furnace also played a crucial role in the American Revolutionary War, as it supplied iron for weapons and ammunition used by the Continental Army. Additionally, the furnace was operated by skilled ironworkers, many of whom were enslaved Africans, highlighting the important role that enslaved labor played in the early American economy.

The Scranton Iron Furnace

A key site in the development of the iron and steel industry in the United States during the 19th century. The furnace was one of the largest and most productive iron furnaces in the country during its period of operation. The Scranton Iron Furnace played a crucial role in the growth of the iron and steel industry in the region, providing the raw materials needed for the construction of infrastructure, such as bridges and railroads, that helped to spur economic growth and industrialization.The Scranton Iron Furnace also represents an important period in the history of American labor, as it was one of the first sites to employ a large number of immigrant workers from Ireland and other countries. These workers faced difficult working conditions and low wages, but their efforts helped to lay the foundation for the growth of the American middle class. The Scranton Iron Furnace is now a historic site, preserved as a monument to the country's industrial heritage, and serves as a reminder of the sacrifices and contributions of the workers who helped to build the United States into the industrial powerhouse it is today.

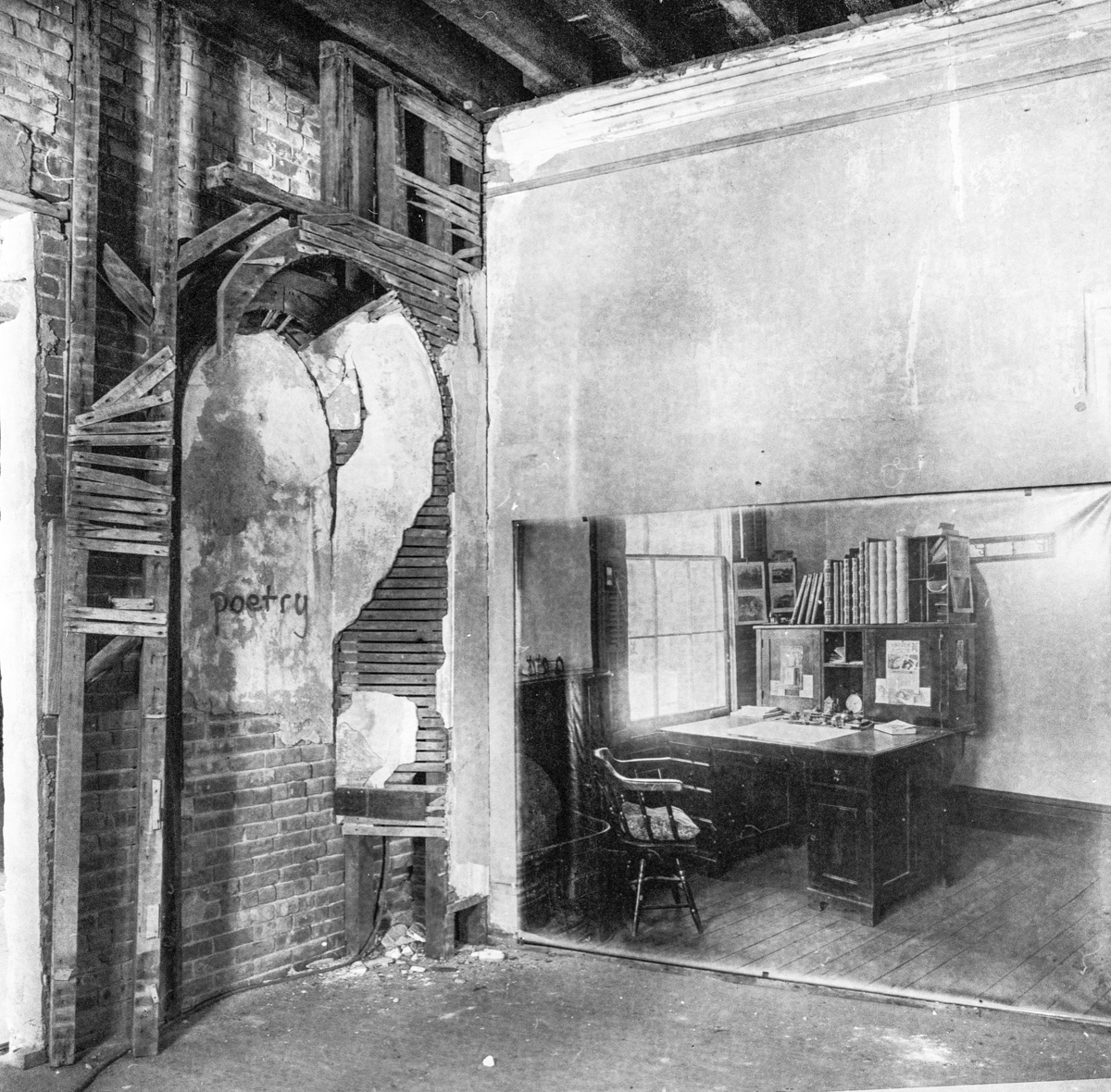

West Point Foundry Office - Cold Spring, New York

West Point Foundry Office - Cold Spring, New YorkThe West Point Iron Foundry

Represents the early development of iron production in the United States during the 19th century. It was the first government-owned iron foundry in the country and played a crucial role in the country's industrialization and economic growth. An Iron mine that supplied the foundry - NY

An Iron mine that supplied the foundry - NYEstablished in 1818 and in operation until 1911, it produced iron castings for various purposes such as weapons, tools, and machinery including some of America’s first steam engines, locomotives, pipes for New York City’s water system and cannons that helped win the Civil War. It also produced a wide range of iron products for civilian use, including engines, boilers, and other machinery.

In 2021, the West Point Foundry Archeological Site, which includes foundry remains and nearby Foundry Dock Park, was designated a National Historic Landmark, the federal government’s highest recognition for places that increase understanding of America’s past.

Pattern shop

Pattern shop Foundry Office

Foundry Office

Bull Hill Mine

Bull Hill Mine Marmora Open Pit Mine - Ontario, Canada

Marmora Open Pit Mine - Ontario, Canada Ball mill at an iron prep facility in NY

Ball mill at an iron prep facility in NY

Conveyors at an iron prep facility in NY

Cambria Iron Company - Pennsylvania

Cambria Iron Company - PennsylvaniaSTEEL

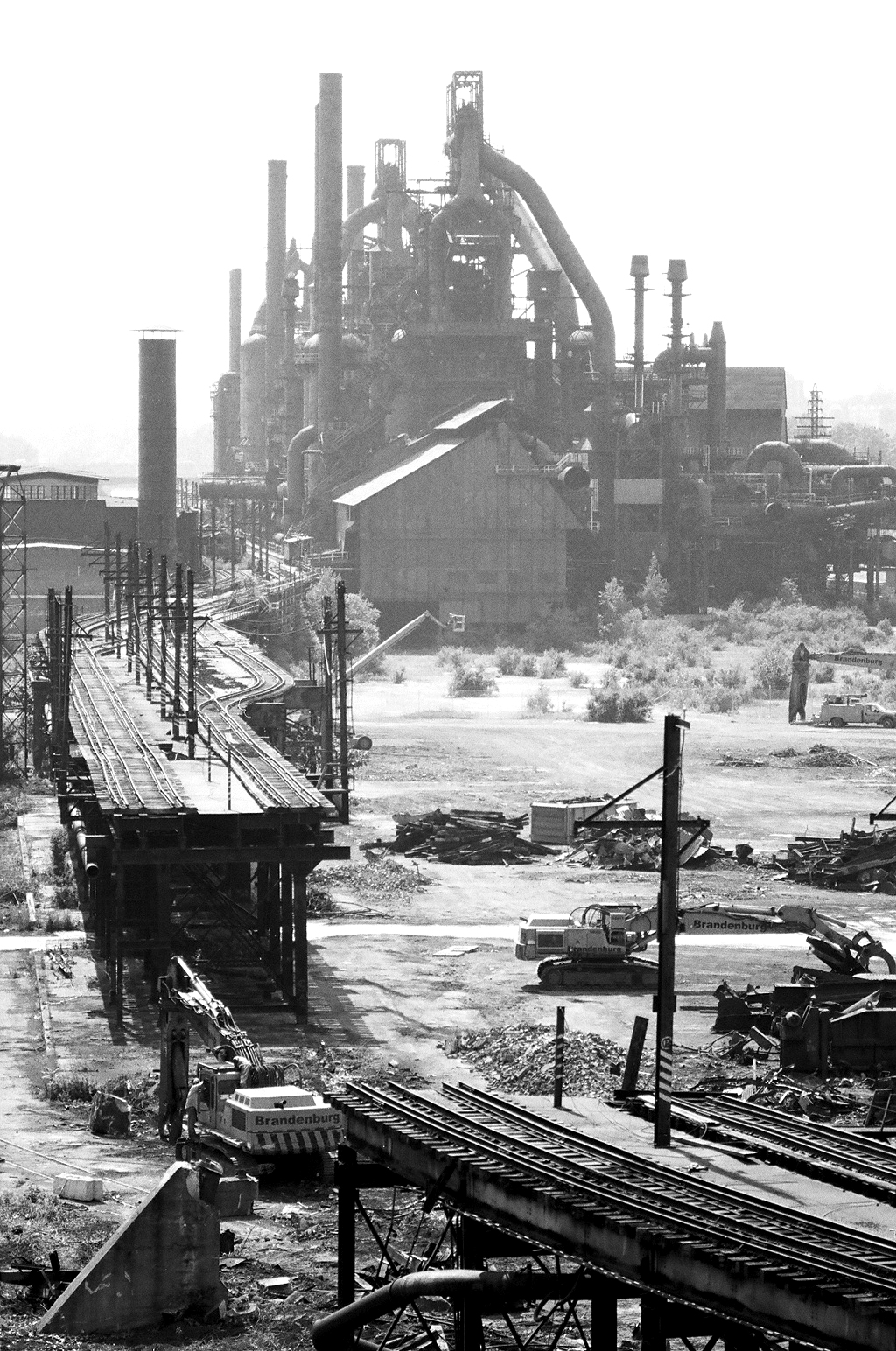

Betlehem Steel - Sparrows Point, Maryland

Betlehem Steel - Sparrows Point, Maryland

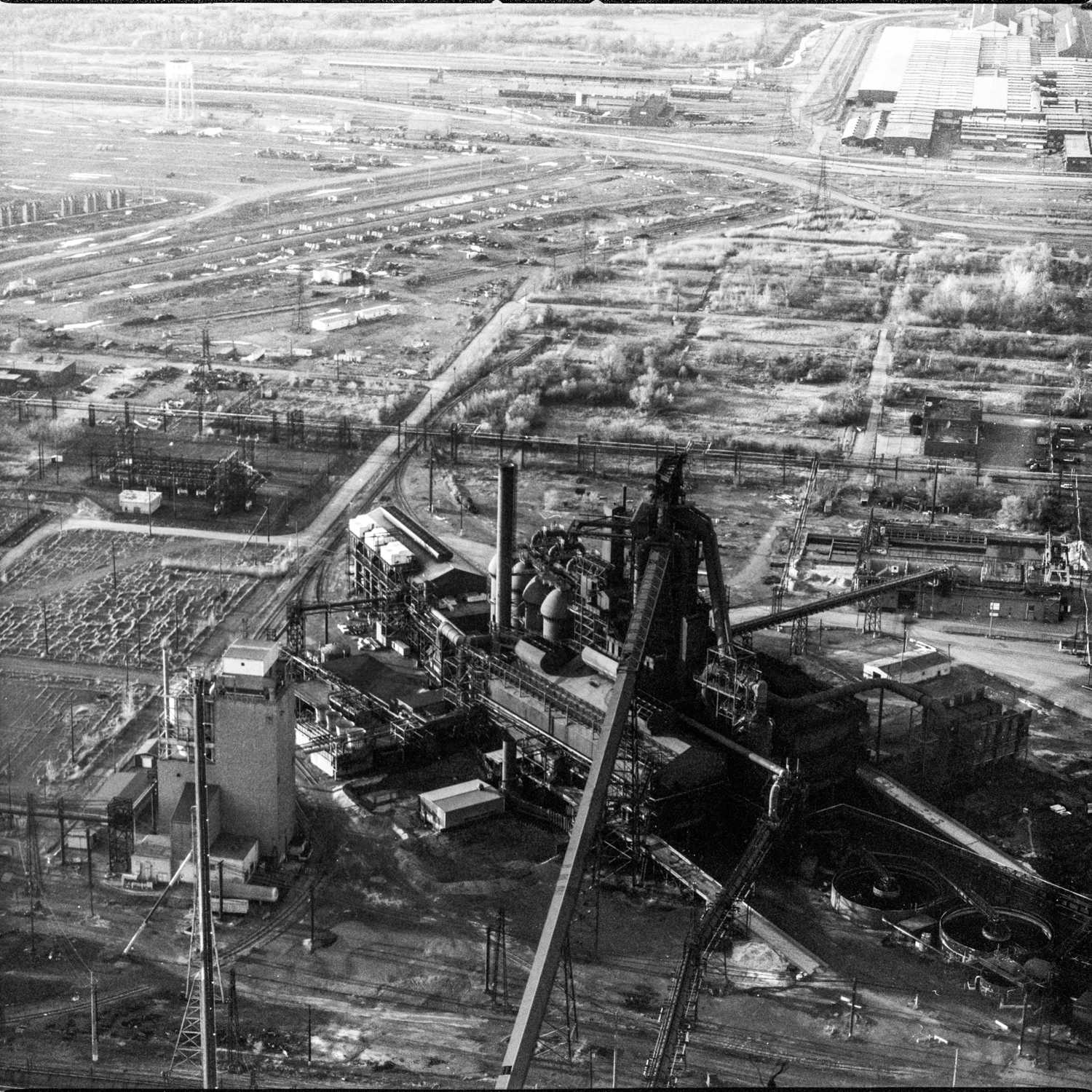

Aerial view of former Bethlehem Steel blast furnace - Sparrows Point, MD - Demolished 2008

Bethlehem Steel - Pennsylvania - 2001

Bethlehem Steel - Pennsylvania - 2001

Bethlehem Steel - Pennsylvania - 2004

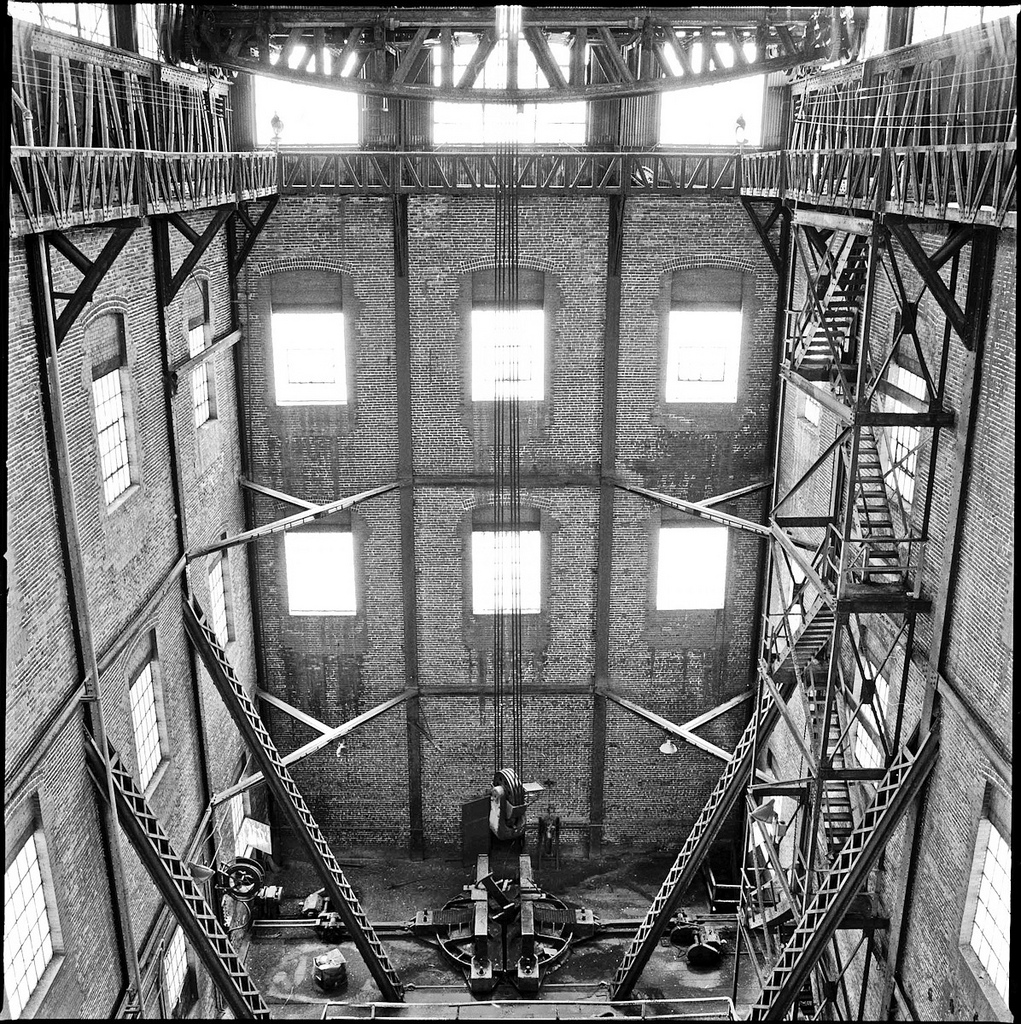

Bethlehem Steel - Powerhouse - Pennsylvania - 2002

Bethlehem Steel - High House - 2003

Bethlehem Steel - Mack Model C Fire Engine - 2008

Bethlehem Steel - Sand Casino Construction

Bethlehem Steel - Hoover-Mason Trestle and blast furnaces

Bethlehem Steel Blast Furnaces from the powerhouse - 35mm HIE

Bethlehem Steel Blast Furnaces from the powerhouse - 35mm HIE

Bethlehem Steel - No2 Machine Shop

Bethlehem Steel - Morgan 250 ton crane

Blast Furnace A and Stockhouse - Bethlehem, PA

Blast Furnace A and Stockhouse - Bethlehem, PA

Demolition of the weldment facility - Bethlehem, PA

Demolition of the Hoover-Mason Trestle - Bethlehem, PA

Casino Construction from the Hoover-Mason trestle

Casino Construction from the Hoover-Mason trestle Bethlehem Steel - Buffalo New York

Bethlehem Steel - Buffalo New York

Perriscope building - California

The Mrs Charles M. Schwabb School

Founded in 1917 by Charles M. Schwabb as a tribute to his wife, Emma Eurana Dinkey Schwabb. The school was built in the Renaissance Revival architectural style and was designed by the renowned architect, Henry Hornbostel. The school was initially established as a residential school for girls from families of modest means and provided them with a high-quality education. The curriculum at the school was designed to provide students with a well-rounded education that focused on academic, cultural, and physical development.

Charles M. Schwabb was a prominent figure in the rail and steel industry during the late 19th and early 20th centuries. He started his career as an engineer at the Edgar Thomson Steel Works in Pittsburgh, Pennsylvania, before moving on to work for the Carnegie Steel Company. Schwabb eventually rose to become the president of the United States Steel Corporation in 1901, a position he held until 1932. During his tenure, he oversaw the expansion of the company and was instrumental in the development of the American steel industry. He was also a noted philanthropist and supported a number of charitable causes, including the establishment of the Mrs Charles M. Schwabb School in Weatherly, PA. His legacy in the rail and steel industry and his commitment to philanthropy continue to be celebrated and remembered to this day.

Mrs Charles M. Schwabb School - Weatherly PA

Mrs Charles M. Schwabb School - Weatherly PA

Lehigh Valley Railroad Locomotive Shop - Weatherly PA - Demolished

Lehigh Valley Railroad Locomotive Shop - Weatherly PA - Demolished Lehigh Valley Railroad Locomotive Shop No.2 - Weatherly PA - Demolished

Lehigh Valley Railroad Locomotive Shop No.2 - Weatherly PA - Demolished

Martin Tower Barbershop

Martin Tower Barbershop Martin Tower Exterior

Martin Tower Exterior Martin Tower Staircase

Martin Tower Staircase

Martin Tower Demolition - Bethlehem PA

Martin Tower Demolition - Bethlehem PA

Martin Tower Demolition - Bethlehem PA

Martin Tower Demolition - Bethlehem PA

Martin Tower - 2015

Martin Tower - 2019

Martin Tower - 2020

Martin Tower - 2020Pier 70 - Union Iron Works / Bethlehem Shipbuilding - San Francisco

The Shipyard at Pier 70 in San Francisco played a crucial role in the city's history and in the development of the United States' maritime industry. During World War II, the shipyard played a vital role in the production of Liberty ships, which were critical to the US war effort. The shipyard also produced other types of vessels, including oil tankers and cargo ships, making it a major center of shipbuilding and repair in the country.

In addition to its industrial significance, the Shipyard at Pier 70 also represents the cultural and social history of San Francisco. The shipyard employed thousands of workers, many of whom were immigrants or members of minority groups, and played a key role in the city's economy and community. The shipyard also represents the development of the city itself, from its early days as a bustling port town to its growth into one of the largest cities in the United States.

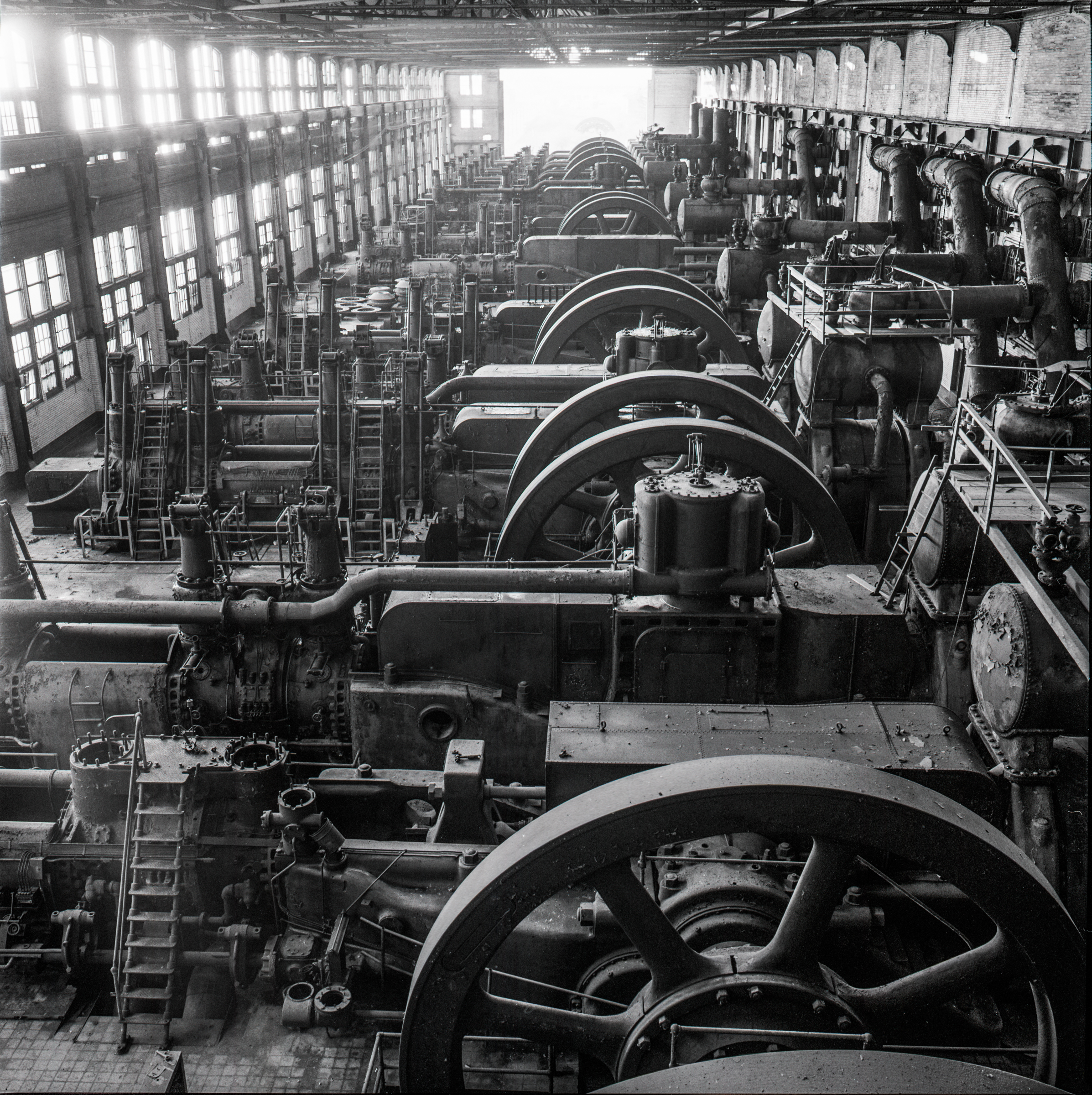

Union Iron Works Machine Shop - Pier 70, San Francisco

Union Iron Works Machine Shop - Pier 70, San Francisco

Chicago Pneumatic electric powered compressors

Chicago Pneumatic electric powered compressors Slipways

SlipwaysPOWER

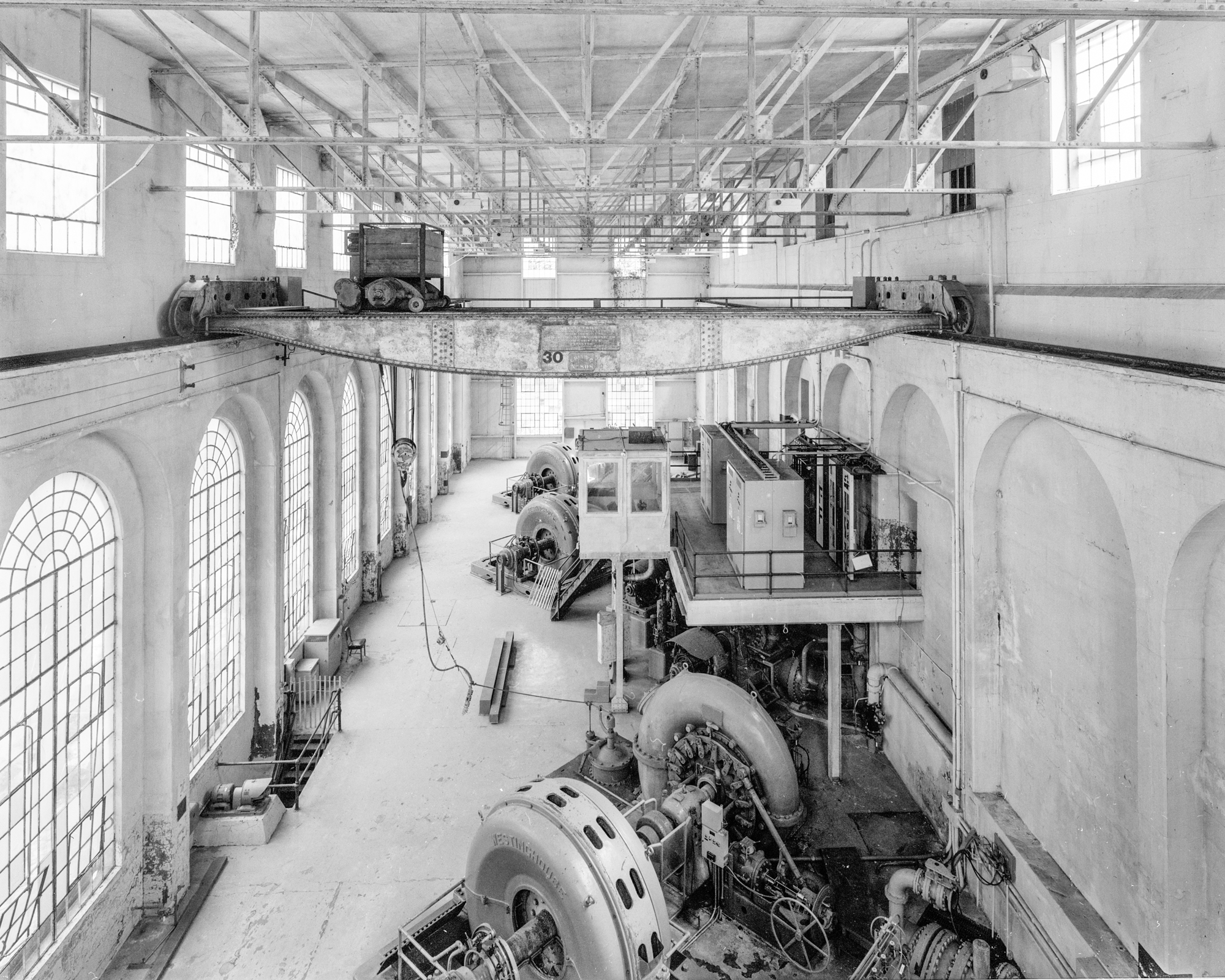

Bullrun powerhouse

Bullrun powerhouse

Bullrun Powerhouse, turbine hall - Oregon

Bullrun Powerhouse, turbine hall 2 - Oregon

Bullrun Powerhouse, turbine hall 2 - Oregon Bullrun Powerhouse, blacksmith shop - Oregon

Bullrun Powerhouse, blacksmith shop - Oregon

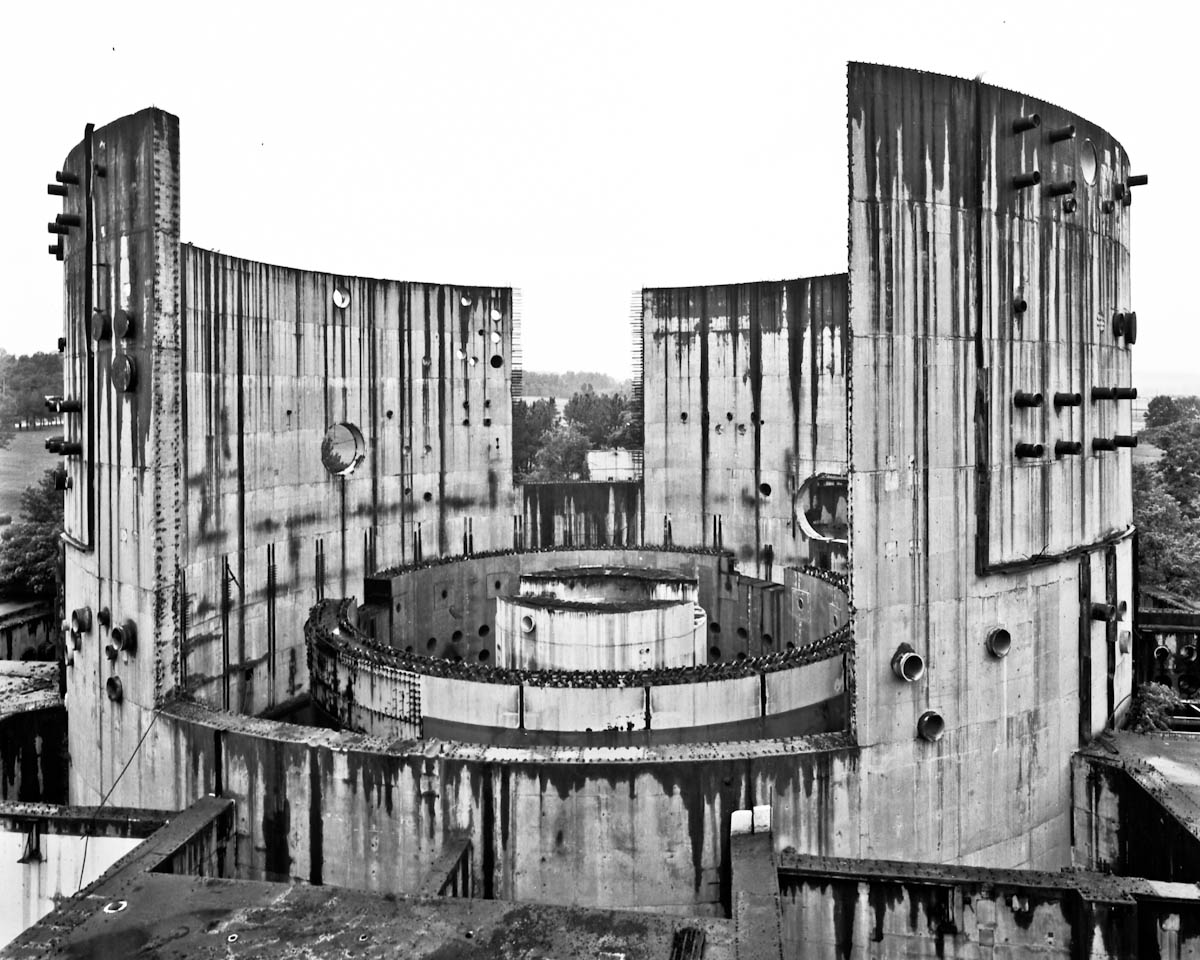

Partially constructed nuclear power plant - cooling tower

Partially constructed nuclear power plant - cooling tower Partially constructed nuclear power plant - containment vessel

Partially constructed nuclear power plant - containment vessel  Marble Hill nuclear power plant - demolition

Marble Hill nuclear power plant - demolition Partially constructed nuclear power plant - containment vessel No.2

Partially constructed nuclear power plant - containment vessel No.2

Partially constructed nuclear power plant - fuel storage

Partially Constructed Nuclear Power Plant

Partially Constructed Nuclear Power Plant

Marble Hill nuclear power plant - containment vessel 2 - demolition

Partially constructed nuclear power plant - condenser chamber

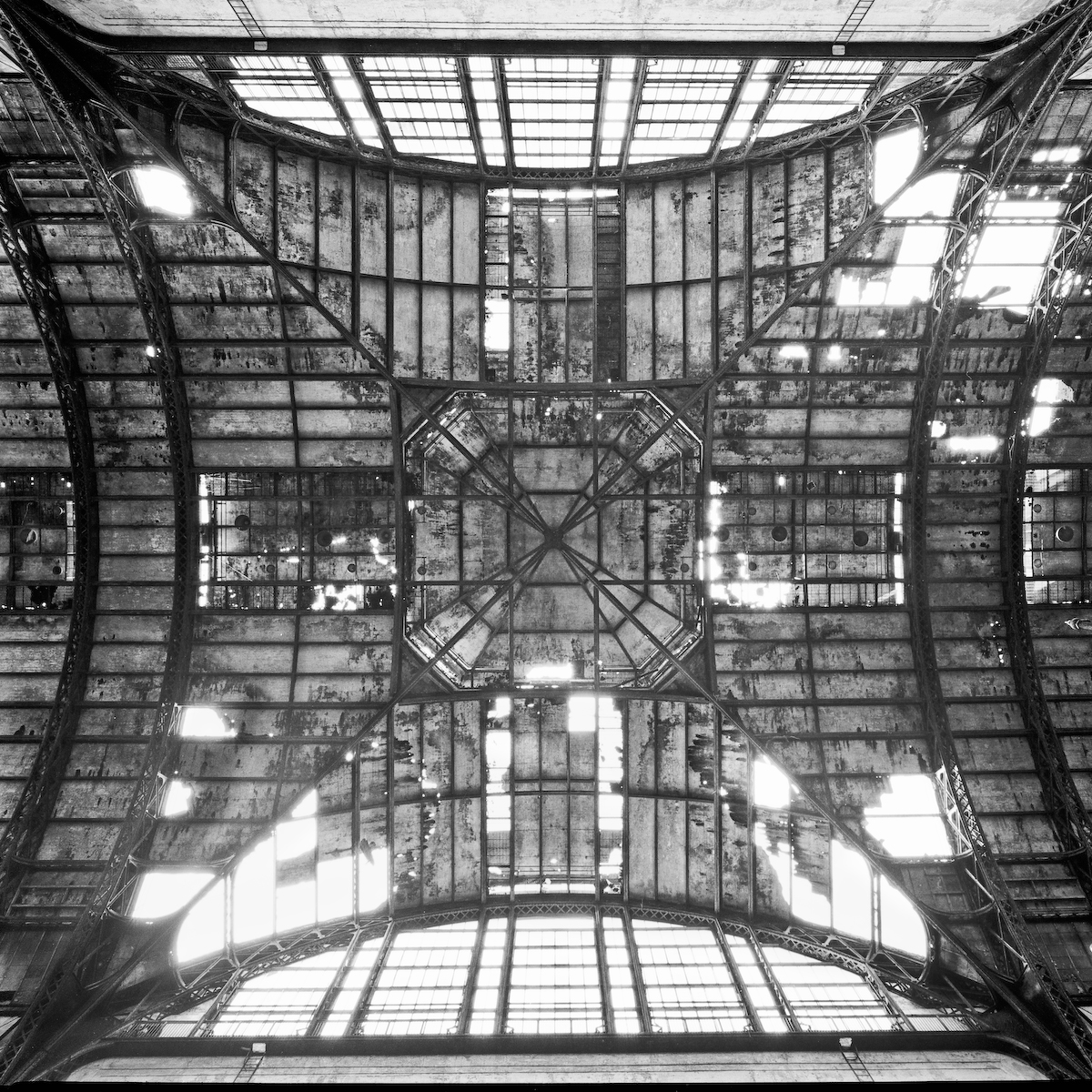

Coal powered generating station - Turbine Hall

Coal powered generating station - Turbine Hall

Neoclassical generating station - Control Room Exterior

Neoclassical generating station - Control Room Exterior Neoclassical generating station - turbine hall No.4

Neoclassical generating station - turbine hall No.4

Marble Hill nuclear power plant - containment vessel - demolition

Partially constructed nuclear power plant - containment vessel No.3

Partially constructed nuclear power plant - containment vessel No.3

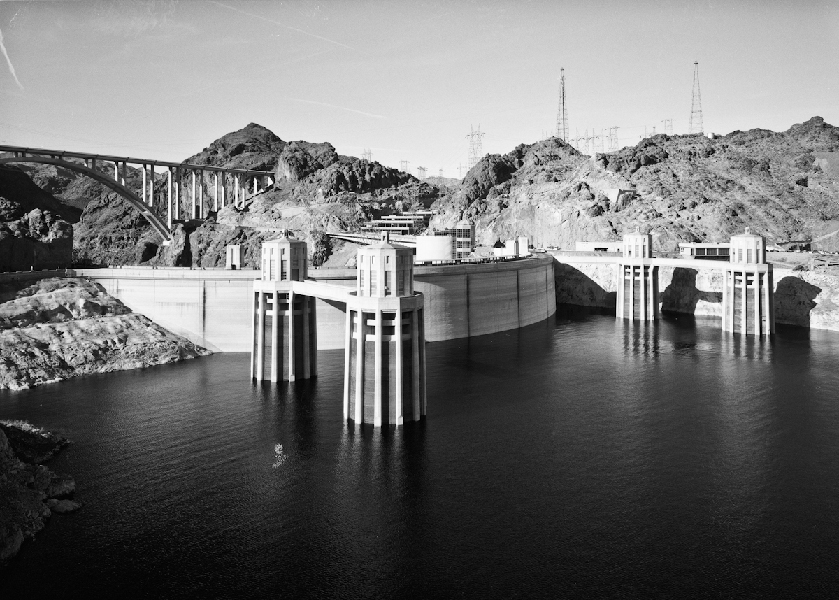

Hoover Dam 2016

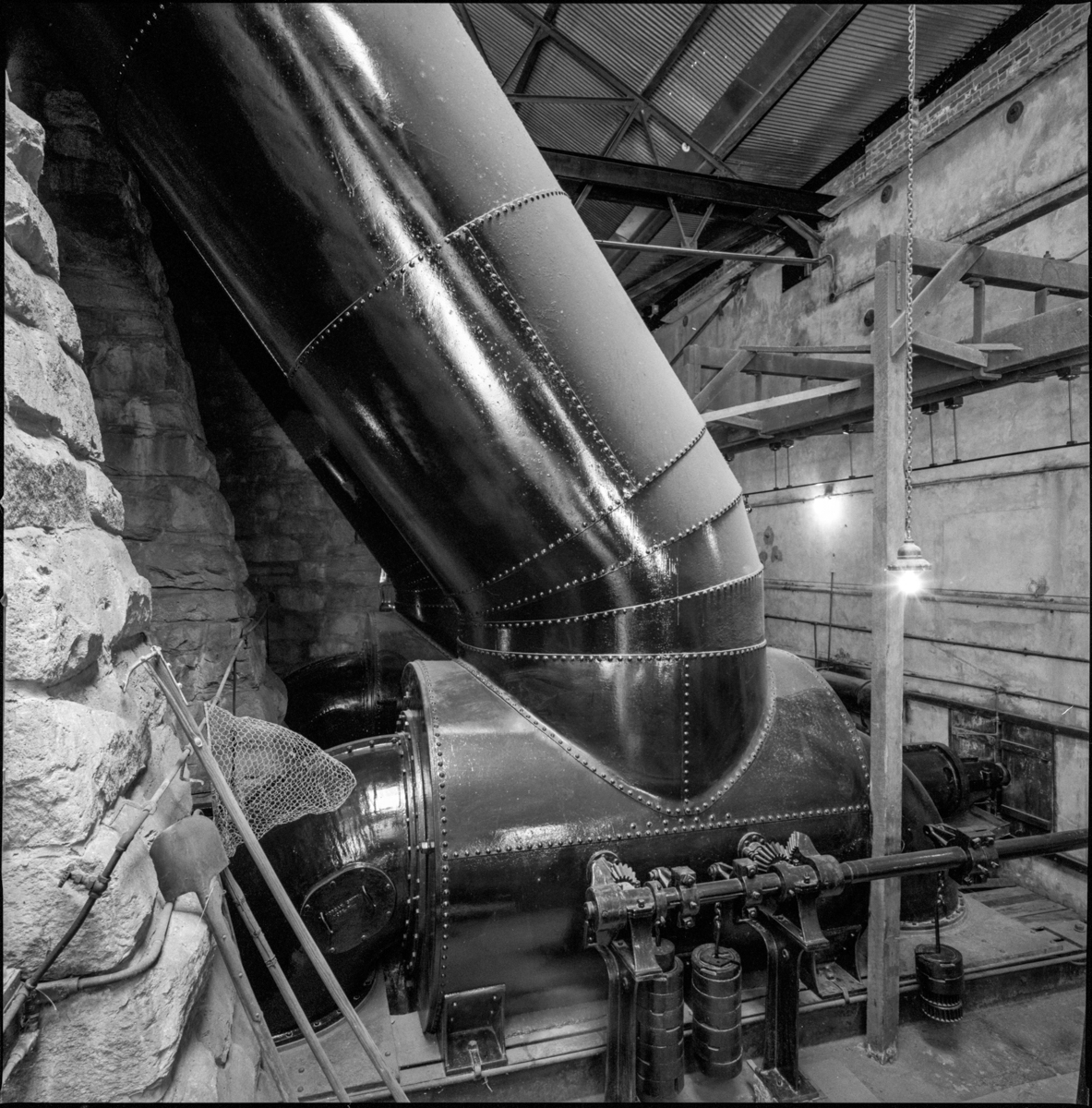

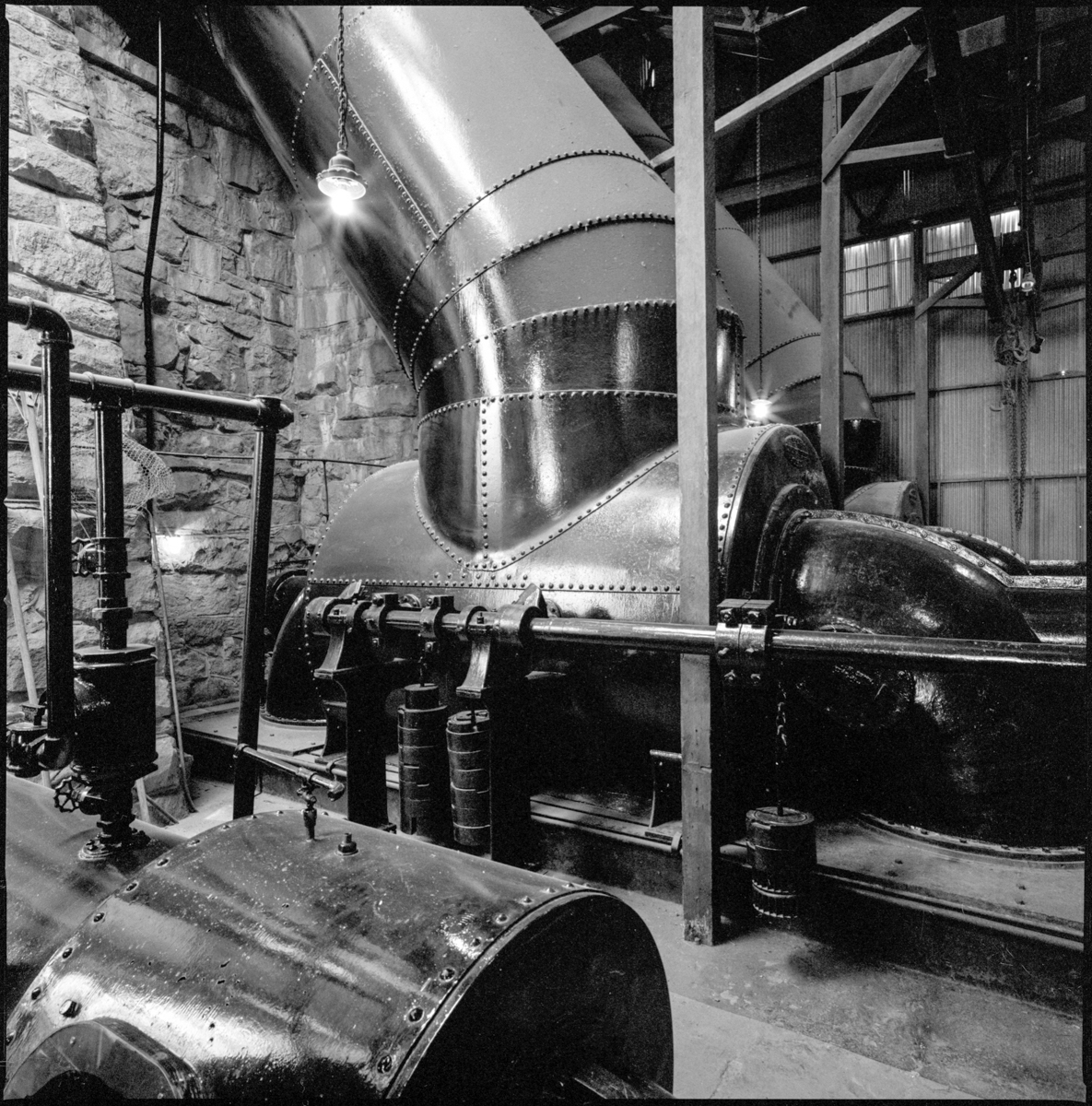

Folsom Power House, Penstocks - California

Folsom Power House | California

Folsom Power House | California Folsom Power House, Penstocks No.2 - California

Folsom Power House, Penstocks No.2 - CaliforniaRAIL

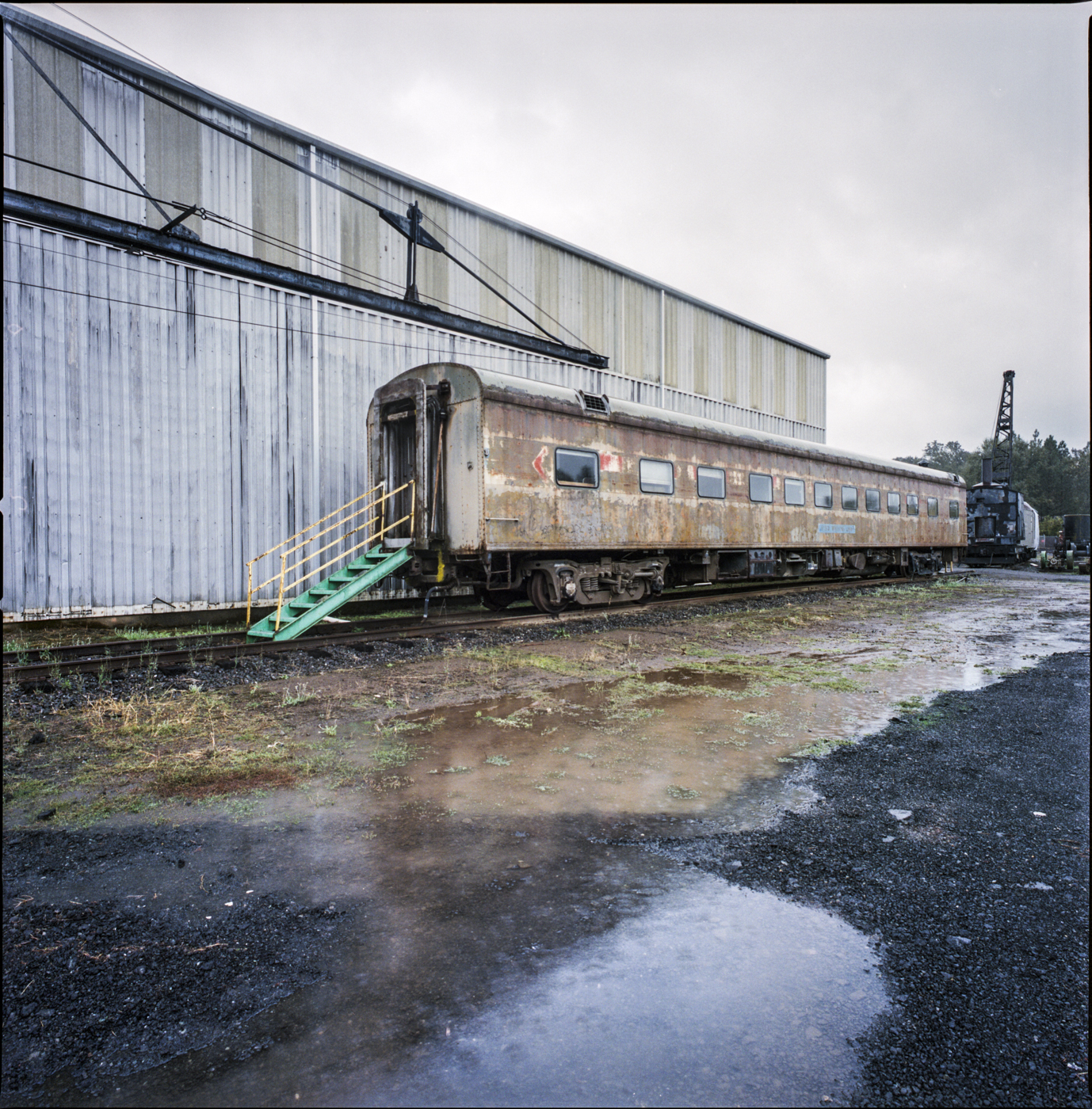

Roots of Motive Power, California

Roots of Motive Power No.2 , California

Roots of Motive Power No.3 , California

Roots of Motive Power No.4 , California

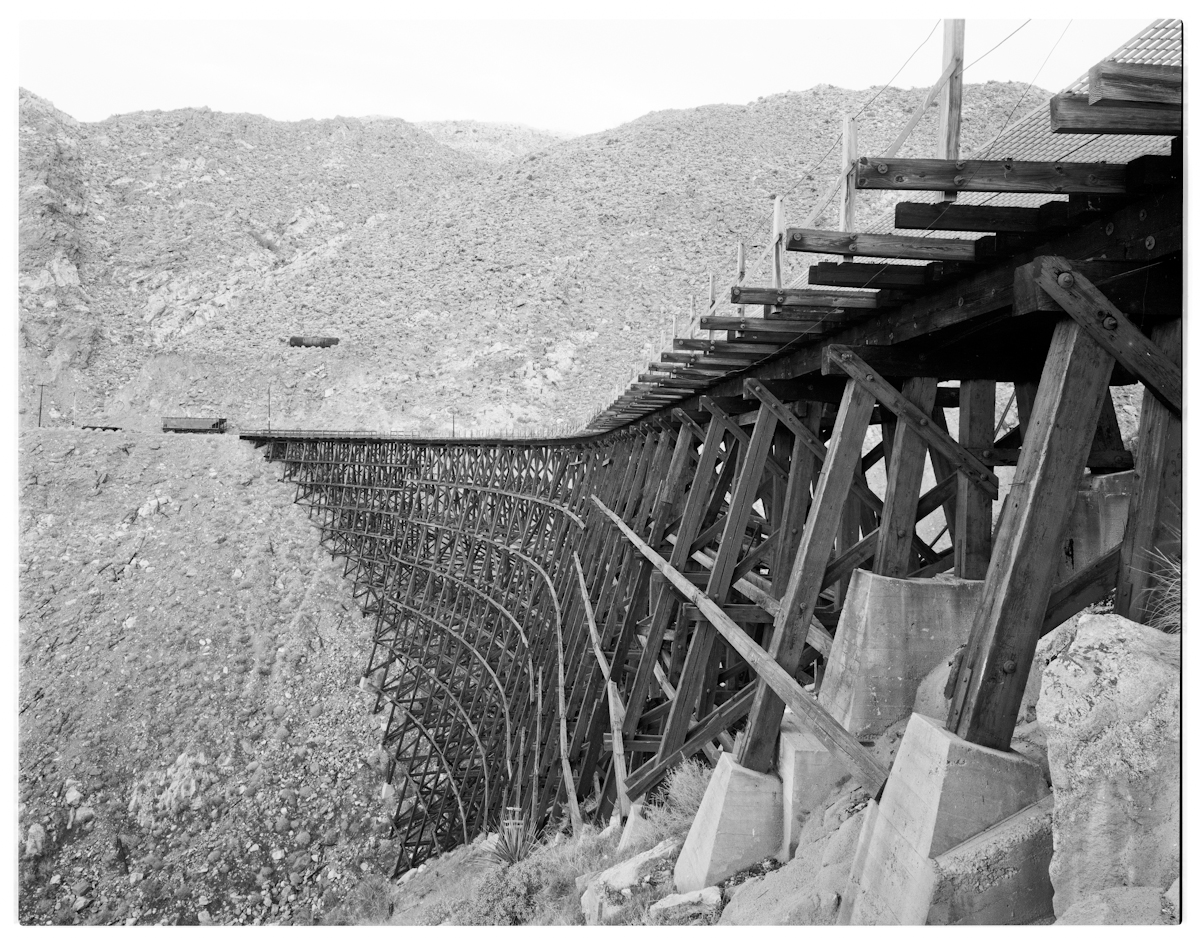

Goat Canyon Trestle - California - 6x6 Archival Negative

Goat Canyon Trestle #2- California

Goat Canyon Trestle - California

Goat Canyon Trestle - California

Goat Canyon Trestle - California - 4x5 Archival Negative

Goat Canyon Tunnel Collapse - California

Carizzo Gorge Railroad

Carizzo Gorge Railroad

Goat Canyon Trestle - California

The Impossible Railroad Collapse - North

The Impossible Railroad Collapse - North

The Impossible Railroad Collapse - South

The Impossible Railroad Collapse - South Goat Canyon Trestle

Goat Canyon Trestle

Goat Canyon Trestle

Wrights Station - 100 year comparison

East Broad Top No.2 - Pennsylvania

East Broad Top No.2 - Pennsylvania

East Broad Top Railroad Roundhouse - Pennsylvania

Corizzo Gorge - California

Grade Crossing Elimination Tunnel 1914 - New York City

Grade Crossing Elimination Tunnel 1914 - New York City

Corizzo Gorge - California

Narrow Guage Rail Tunnel - Pennsylvania

Mountain Charlie Tunnel, South Portal

Mountain Charlie Tunnel, South Portal  Oxford Tunnel

Oxford Tunnel

Tunnel Zero - The Transcontinental Railroad

Tunnel Zero (No.2) - The Transcontinental Railroad

Virginia & Truckee Railroad -Tunnel collapse

Manunka Chunk Tunnels - Delaware, Lackawanna & Western RR - New Jersey

Manunka Chunk Tunnels - Delaware, Lackawanna & Western RR - New Jersey  Narrow Guage Rail Tunnel #2 - Pennsylvania

Narrow Guage Rail Tunnel #2 - Pennsylvania Freedom Tunnel - New York - 2003

Freedom Tunnel - New York - 2003 Lofty Tunnels - Pennsylvania

Lofty Tunnels - Pennsylvania Snowsheds in the Sierra Nevada Mountains

Snowsheds in the Sierra Nevada Mountains

Grade Crossing Elimination Tunnel No.1 - Brooklyn

Reading Viaduct - Philadelphia

Reading Viaduct - Philadelphia

Boxcar derailment

Corizzo Gorge Derailment - California

Corizzo Gorge Derailment - California Rail Yard - Detroit, Michigan

Rail Yard - Detroit, MichiganThe Atlantic Avenue Tunnel

Created to connect the Long Island Rail Road (LIRR) to the rest of the rail system in Brooklyn. The tunnel was originally built in the 1840s as a means of transporting goods and passengers from the LIRR to the rest of Brooklyn, and was intended to bypass the congested surface streets of the city. The tunnel was also used by streetcars and subways, which operated in the tunnel until 1861. The tunnel was closed to subway service at that time and has been unused since then.

This was the last photo taken before the city shut down access to the tunnel in 2010.

Atlantic Avenue Tunnel - Brooklyn, New York 2010

Atlantic Avenue Tunnel - Brooklyn, New York 2010

Virginia & Truckee Baldwin 4-6-0 #25 - Carson City, NV

Princes Of Wales Bridge - Quebec/Ontario

Princes Of Wales Bridge - Quebec/Ontario East Broad Top Railroad - Turntable

East Broad Top Railroad - Turntable