IRON

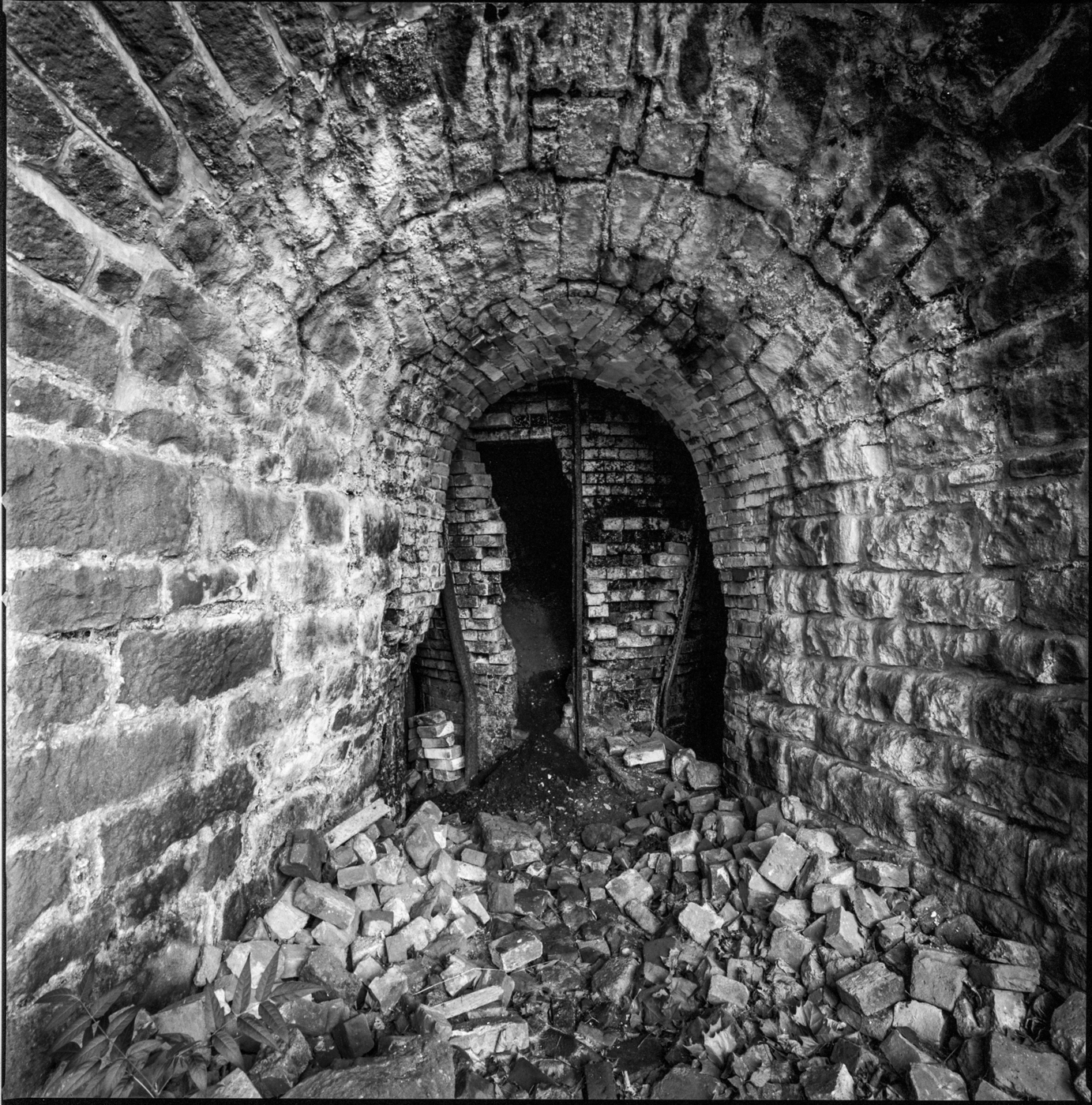

Splitrock (Cobb) Furnace #1 - New Jersey - 1862

Splitrock (Cobb) Furnace #1 - New Jersey - 1862

Splitrock (Cobb) Furnace #2 - New Jersey

Clove Furnace - New Jersey - Completed 1865

Clove Furnace - New Jersey - Completed 1865

Cornwall Furnace - Pennsylvania - 1742

Photographed 2018

Cornwall Furnace - Pennsylvania - 1742

Photographed 2018

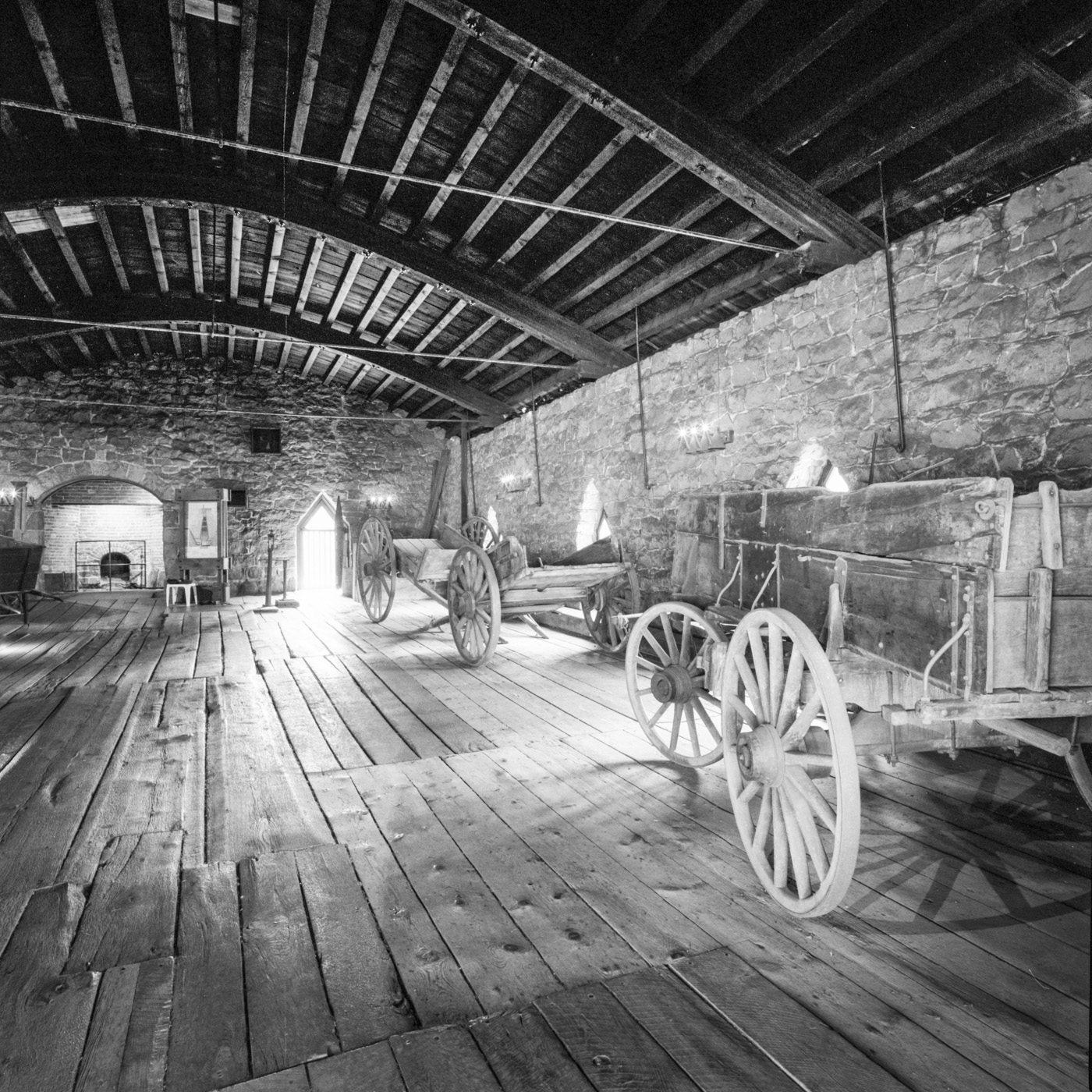

Cornwall Furnace - Charging Floor - Pennsylvania - Built 1742 Photographed 2018

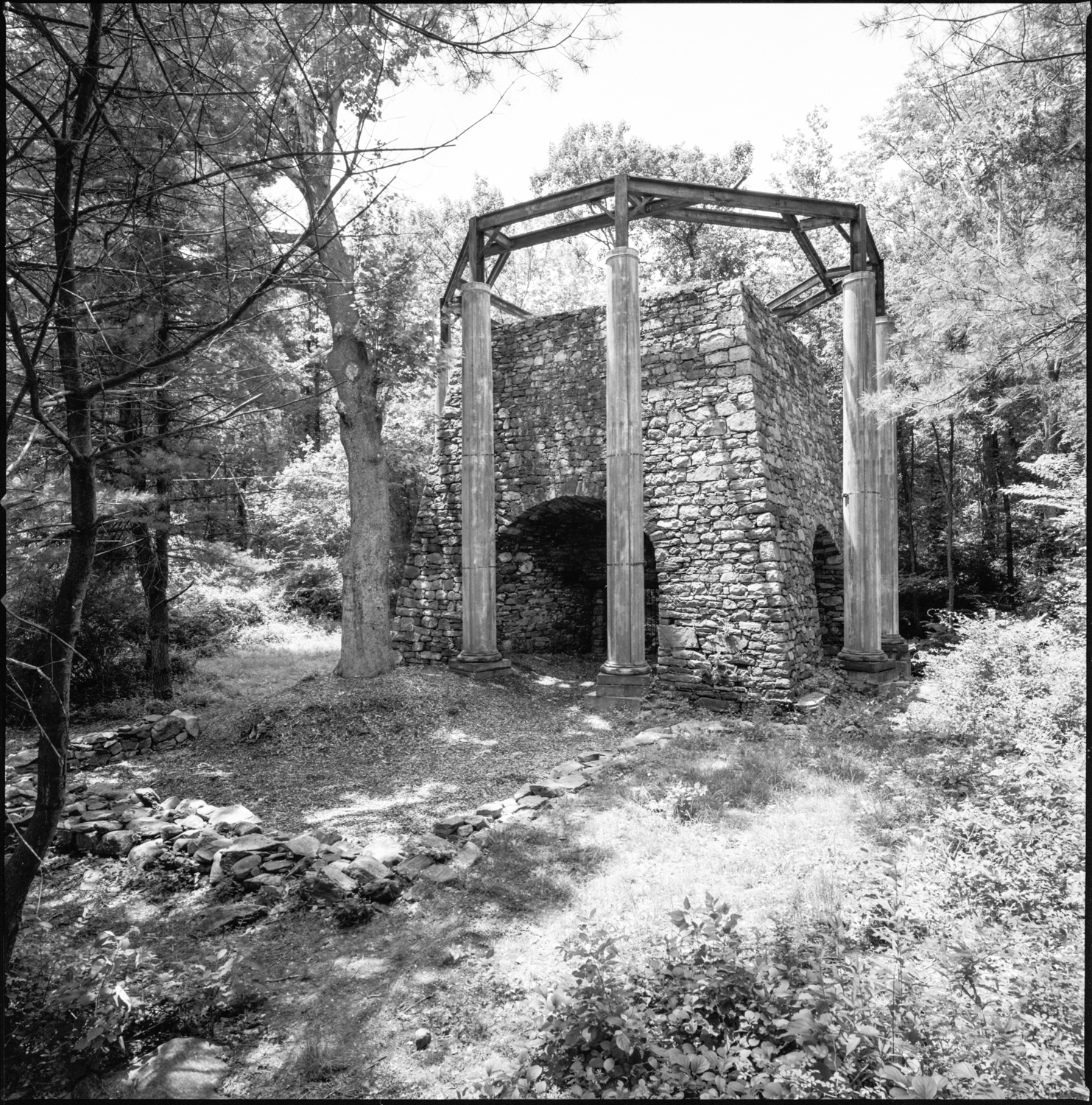

Sterling Furnace - New York

Believed to have been the first place in the State of New York in which iron and steel were manufactured in quantity.

Sterling Furnace - Hoist House Ruins - New York

PLAQUE ONSITE READS:

From the iron here produced was manufactured in 1778, by Peter Townsend, the Great Chain put across the Hudson River, near West Point, to impede the progress of the British war-ships up the river; and the first anchor made in New York State was here manufactured in 1773.

Erected 1906 by Daughters of the Revolution.

West Point Foundry furnace remains - New Jersey - 1817

West Point Foundry furnace remains - New Jersey - 1817

Joanna Furnace - Pennsylvania

Joanna Furnace - Pennsylvania

Joanna Furnace - Pennsylvania

Joanna Furnace - Pennsylvania

Clove Furnace - New Jersey

Hopewell Furnace - Pennsylvania - 1771

Hopewell Furnace - Pennsylvania - 1771

Hopewell Furnace - Pennsylvania - 1771

Splitrock Furnace #3 - New Jersey - 1862

Splitrock Furnace #3 - New Jersey - 1862The Splitrock Iron Furnace

Located in Morris County, New Jersey, it was built in 1862 during the height of the American Civil War. The furnace was constructed by the Split Rock Iron Company, which was formed by a group of local investors who saw the potential for iron production in the area. The furnace was built near a large deposit of iron ore and was powered by a nearby stream, which provided the necessary water to power the furnace's blast machinery.

Splitrock Furnace #4 - New Jersey - 1862

During its peak production years, the furnace produced over 400 tons of iron per month and employed over 200 workers. The iron produced by the furnace was used for a variety of purposes, including the production of weapons and ammunition for the Union army during the Civil War. The furnace also produced iron for other industrial uses such as railroads, bridges, and buildings. However, after the end of the war, demand for iron dropped significantly, and the Splitrock Iron Furnace was forced to close in 1866.

During its peak production years, the furnace produced over 400 tons of iron per month and employed over 200 workers. The iron produced by the furnace was used for a variety of purposes, including the production of weapons and ammunition for the Union army during the Civil War. The furnace also produced iron for other industrial uses such as railroads, bridges, and buildings. However, after the end of the war, demand for iron dropped significantly, and the Splitrock Iron Furnace was forced to close in 1866.

The Oxford Iron Furnace - Built 1741 - Oxford, NJ

The Oxford Iron Furnace - Built 1741 - Oxford, NJThe Oxford Iron Furnace

Represents the early development of the iron industry in the United States during the 18th and 19th centuries. The furnace was built in 1741 and was in operation until 1884, producing iron for various purposes such as weapons, tools, and machinery. The furnace is notable for its use of charcoal as a fuel source, which was the primary fuel used in iron production during the colonial period. The furnace also utilized a blast mechanism, which was a significant technological advancement at the time, that increased the efficiency of the iron production process.The Oxford Iron Furnace also played a crucial role in the American Revolutionary War, as it supplied iron for weapons and ammunition used by the Continental Army. Additionally, the furnace was operated by skilled ironworkers, many of whom were enslaved Africans, highlighting the important role that enslaved labor played in the early American economy.

The Scranton Iron Furnace

A key site in the development of the iron and steel industry in the United States during the 19th century. The furnace was one of the largest and most productive iron furnaces in the country during its period of operation. The Scranton Iron Furnace played a crucial role in the growth of the iron and steel industry in the region, providing the raw materials needed for the construction of infrastructure, such as bridges and railroads, that helped to spur economic growth and industrialization.The Scranton Iron Furnace also represents an important period in the history of American labor, as it was one of the first sites to employ a large number of immigrant workers from Ireland and other countries. These workers faced difficult working conditions and low wages, but their efforts helped to lay the foundation for the growth of the American middle class. The Scranton Iron Furnace is now a historic site, preserved as a monument to the country's industrial heritage, and serves as a reminder of the sacrifices and contributions of the workers who helped to build the United States into the industrial powerhouse it is today.

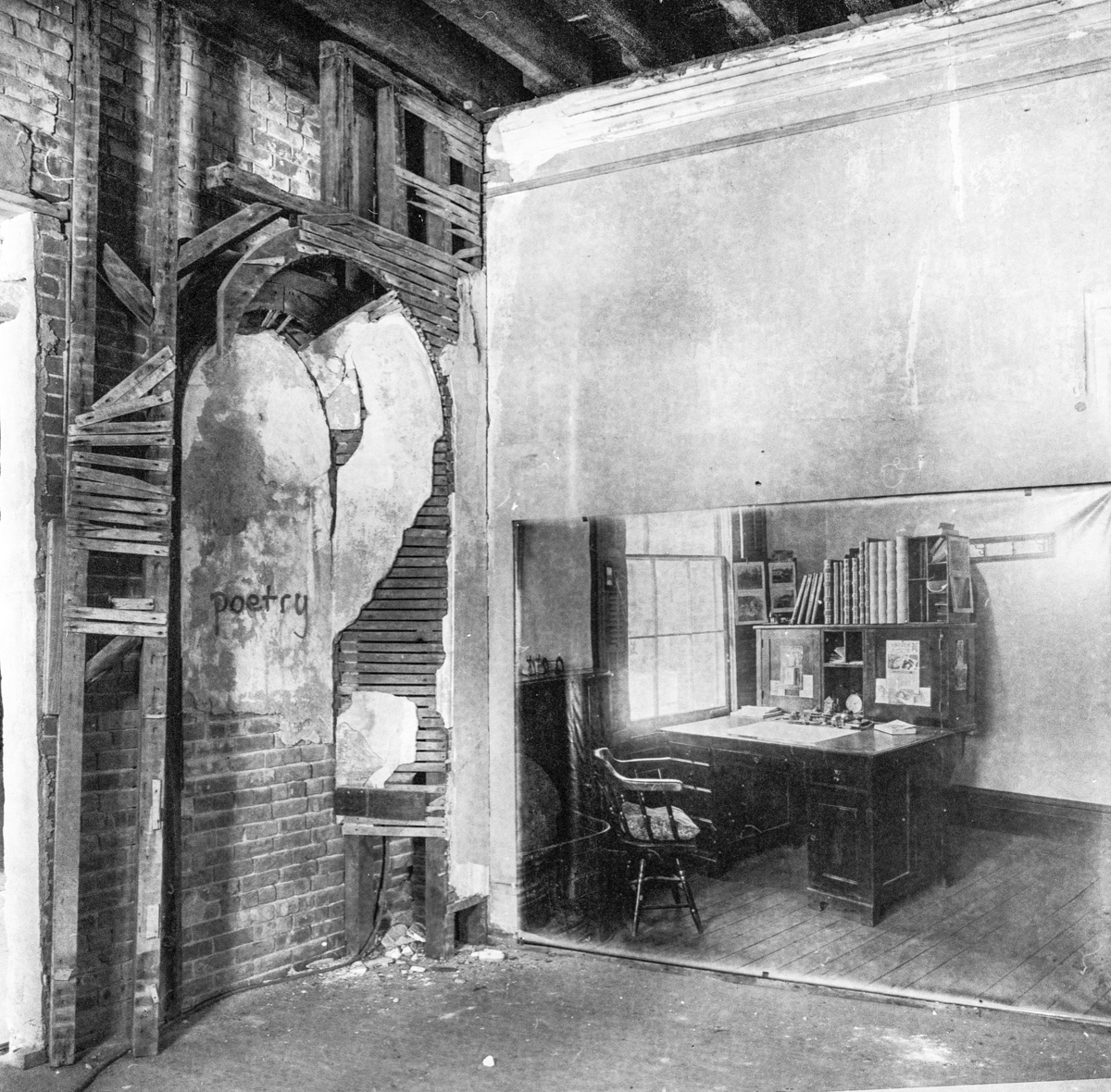

West Point Foundry Office - Cold Spring, New York

West Point Foundry Office - Cold Spring, New YorkThe West Point Iron Foundry

Represents the early development of iron production in the United States during the 19th century. It was the first government-owned iron foundry in the country and played a crucial role in the country's industrialization and economic growth. An Iron mine that supplied the foundry - NY

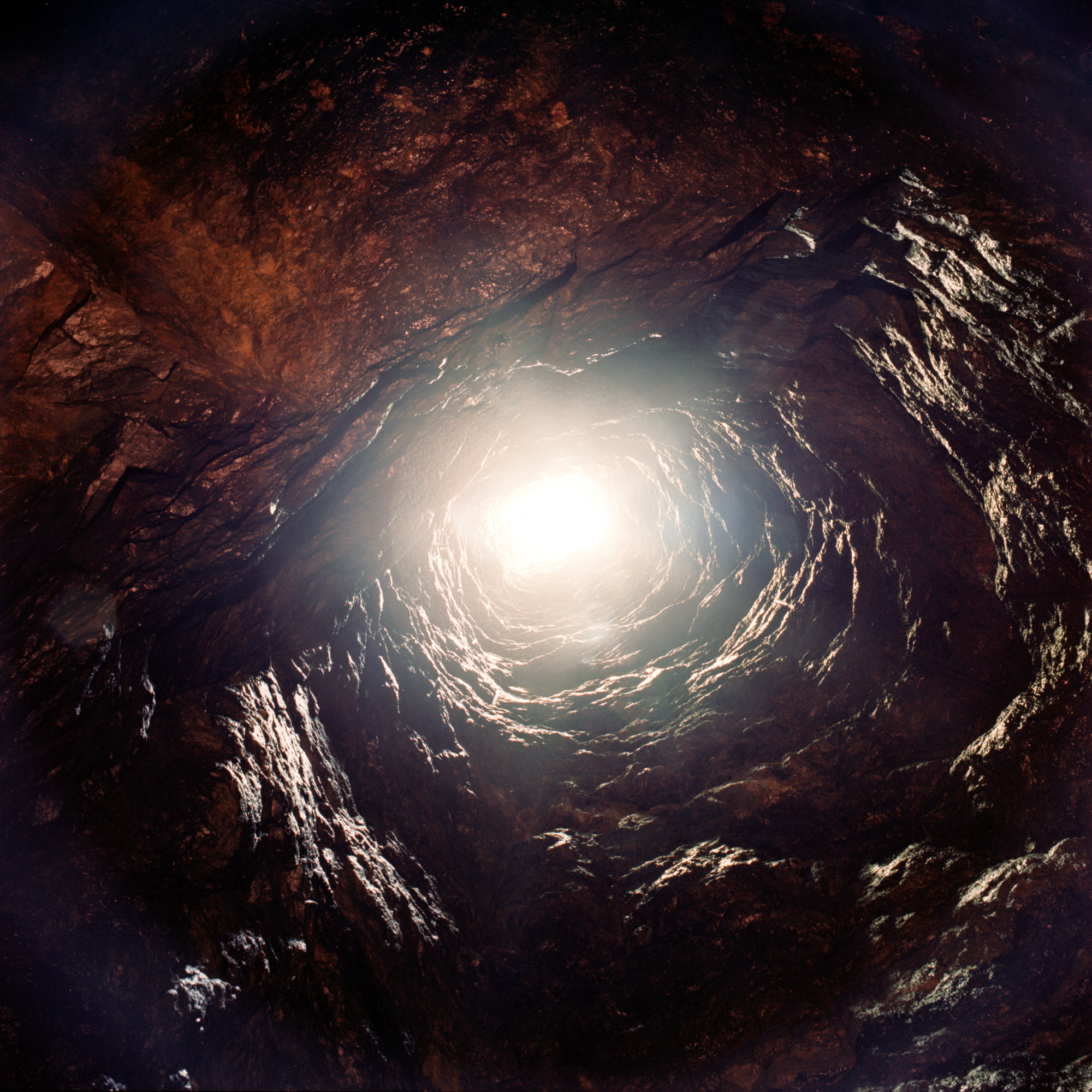

An Iron mine that supplied the foundry - NYEstablished in 1818 and in operation until 1911, it produced iron castings for various purposes such as weapons, tools, and machinery including some of America’s first steam engines, locomotives, pipes for New York City’s water system and cannons that helped win the Civil War. It also produced a wide range of iron products for civilian use, including engines, boilers, and other machinery.

In 2021, the West Point Foundry Archeological Site, which includes foundry remains and nearby Foundry Dock Park, was designated a National Historic Landmark, the federal government’s highest recognition for places that increase understanding of America’s past.

Pattern shop

Pattern shop Foundry Office

Foundry Office

Bull Hill Mine

Bull Hill Mine Marmora Open Pit Mine - Ontario, Canada

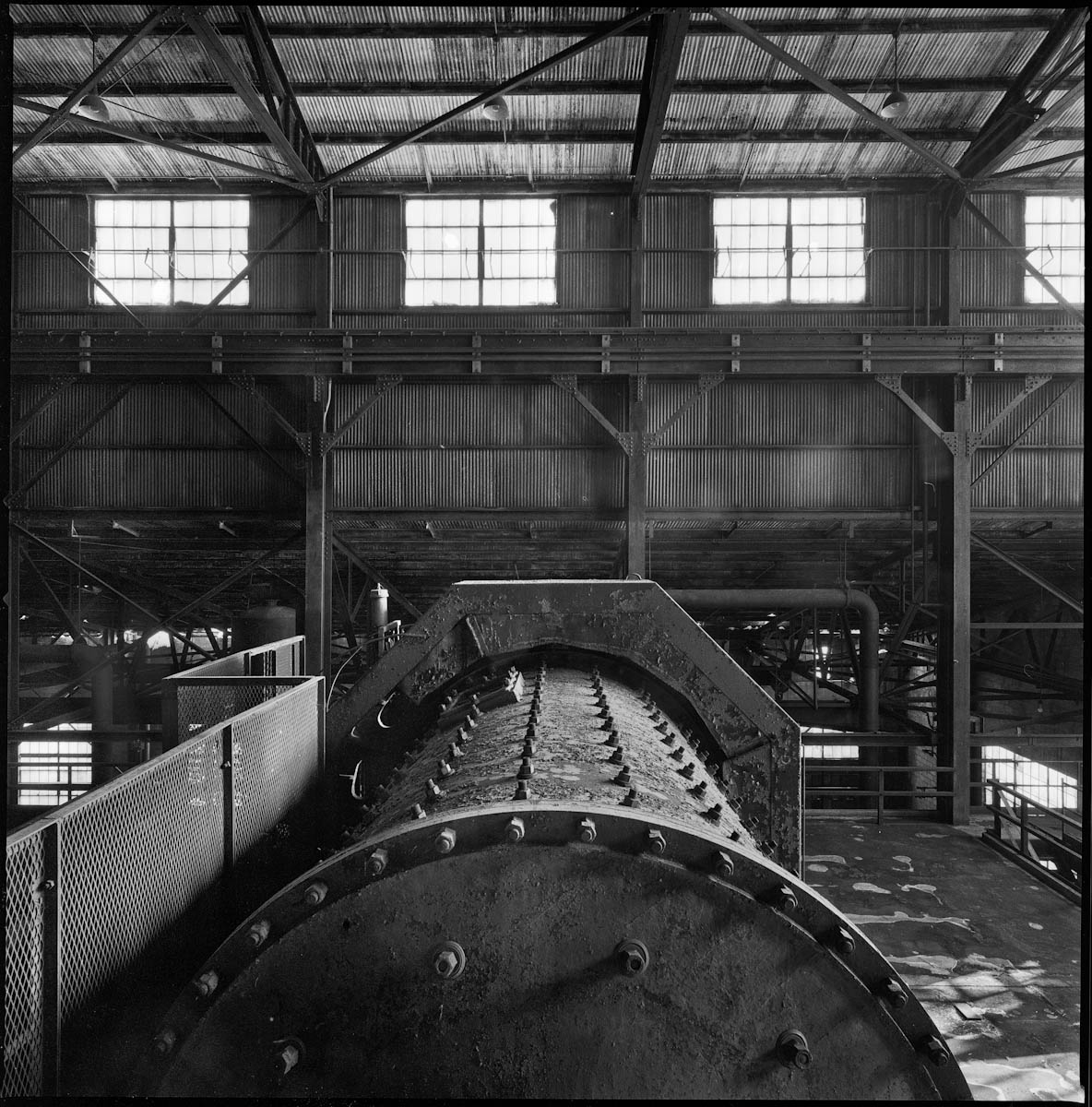

Marmora Open Pit Mine - Ontario, Canada Ball mill at an iron prep facility in NY

Ball mill at an iron prep facility in NY

Conveyors at an iron prep facility in NY

Cambria Iron Company - Pennsylvania

Cambria Iron Company - Pennsylvania